This week our team made significant headway in the 3 main components of our project; the gantry construction, the gantry control systems, and the painting algorithm. A single team member worked in each of these areas, and no significant issues have appeared in our design from what we have been able to achieve this week. The next target on our horizon is creating a short demo of the progress we have made thus far, and believe that we will be able to complete this comfortably in the following week.

No significant risks have appeared from what we have developed this week, but as our individual areas are being completed we are starting to consider the integration of each system. The integration is likely to have some issues arise and to control these factors we have clearly laid out the inputs and outputs of each layer and how they expect communication to happen. Given that we still have ample time left we do not consider this to be a serious risk to our success, but are considering how we can handle this process early to save time in the future.

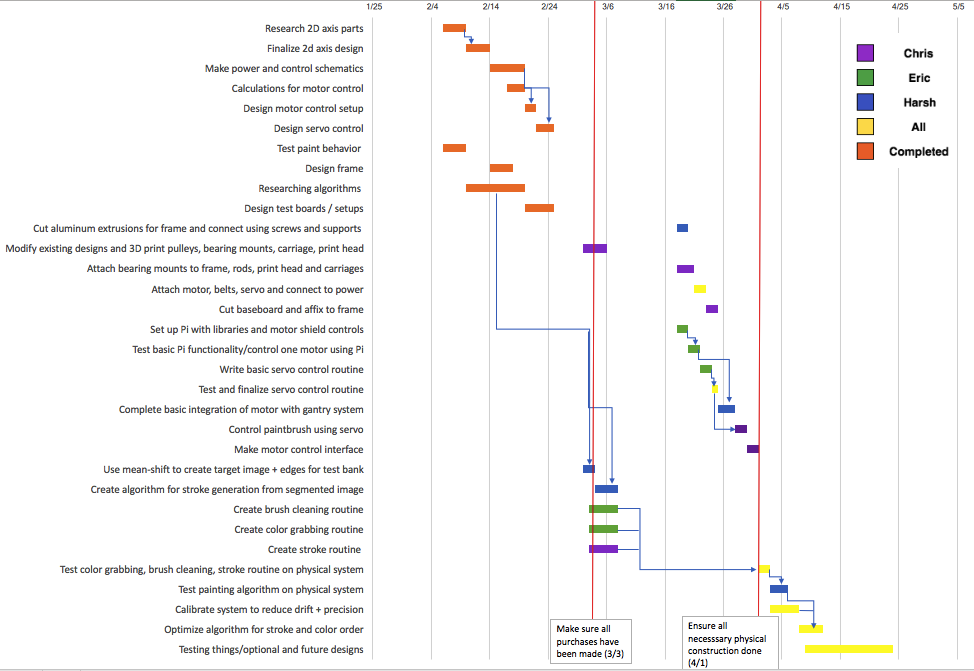

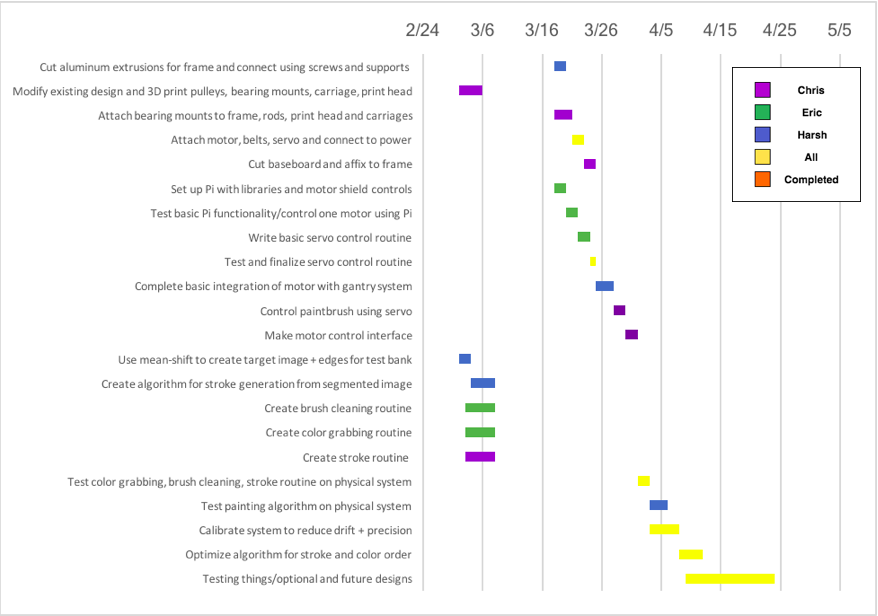

Overall our progress this week has remained mostly on schedule. By our schedule this week should mark the complete construction of the gantry and the successful operation of our motors. While the gantry is not entirely completed, it will be entirely assembled in the next week, and enough is completed that it is not hindering progress in terms of controlling the motors. Motor control has been completed, and the painting algorithm is also underway.

No changes have had to be made to our design, aside from the development of a software model of the gantry system to allow for easier testing of the painting algorithm. This is not part of our final deliverables, but is a part of the development of the painting algorithm. This change was necessary as it allows for much faster testing of the software layer.