The most significant risks that could jeopardize our project is the failure to successfully create the 2D axis gantry system. The three of us are confident in our ability to write a working software algorithm with our experience, but we all lack any significant experience in robotics or mechanical engineering. As a result, we are frontloading the work for the physical aspect of our project, which includes assembling the actual robot as well as getting the hardware component functioning properly. Right now, we are considering several alternatives for procuring the parts necessary for the creation of our gantry system, which is inspired by the gantry system used in Ultimaker 3D printers. Our current plan is to use CAD files that we found online of the Ultimaker gantry parts, such as screws and pulleys, and then customize them to our project specifications and 3D print them. In this approach, we would purchase more generic parts, such as rods and belts, from any source we want that would fit with our modified parts. The risks with this approach are possible structural weaknesses from using the 3D printer filament, possible inaccuracies from 3D printing small parts, and also the danger of parts not fitting together after our customizations. To mitigate these risks, we will test 3D printed parts for their sturdiness and how accurately the smaller details of a part are printed. We will also limit the amount of modifications we make to the parts to reduce the risk of breaking the system. We have several backup plans for obtaining the parts in the situation that our primary plan fails. One alternative is ordering official Ultimaker replacement parts to assemble our gantry system with. However, this approach would limit the customization available to us. On the other hand, it is almost a guarantee that the parts would work and fit together, due to being official replacements. A third possibility is ordering the parts online, but not necessarily all from a single source. We are thinking of using some of the more detailed Ultimaker replacement parts, such as pulleys and sliding blocks, but purchasing more generic components such as belts and rods from other sources. This would allow us to find belts or rods of our desired length, while giving us some freedom to customize. A drawback of this is that it is somewhat difficult to find some parts with certain specifications – for example, finding rods of a 8mm diameter that would fit with the Ultimaker parts.

We did not previously lock down many specifics for our design, so nothing significant has changed from our vision for the project and the requirements we detailed in our proposal. However, we are beginning to finalize decisions for the parts we plan to use as well as the specifications for our system, and how all the parts will fit together.

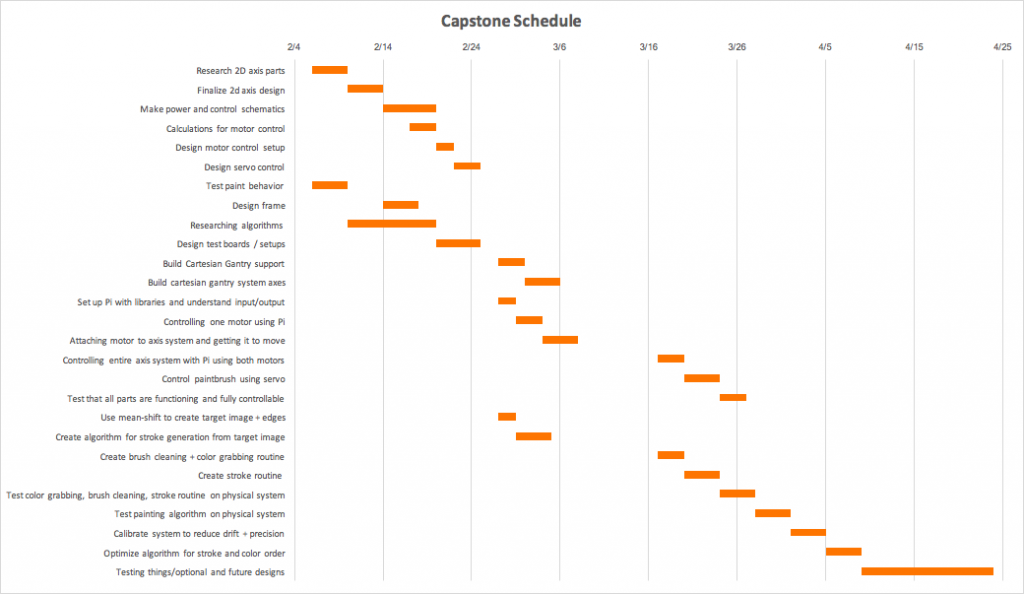

Below is our updated schedule: