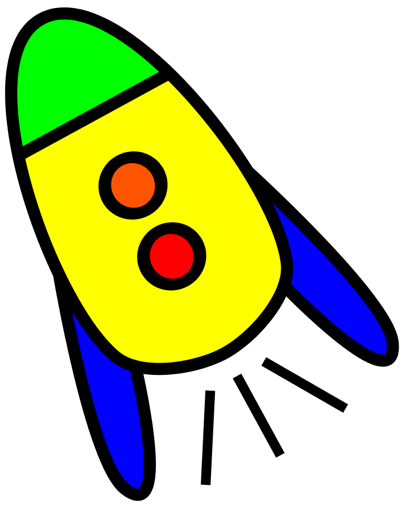

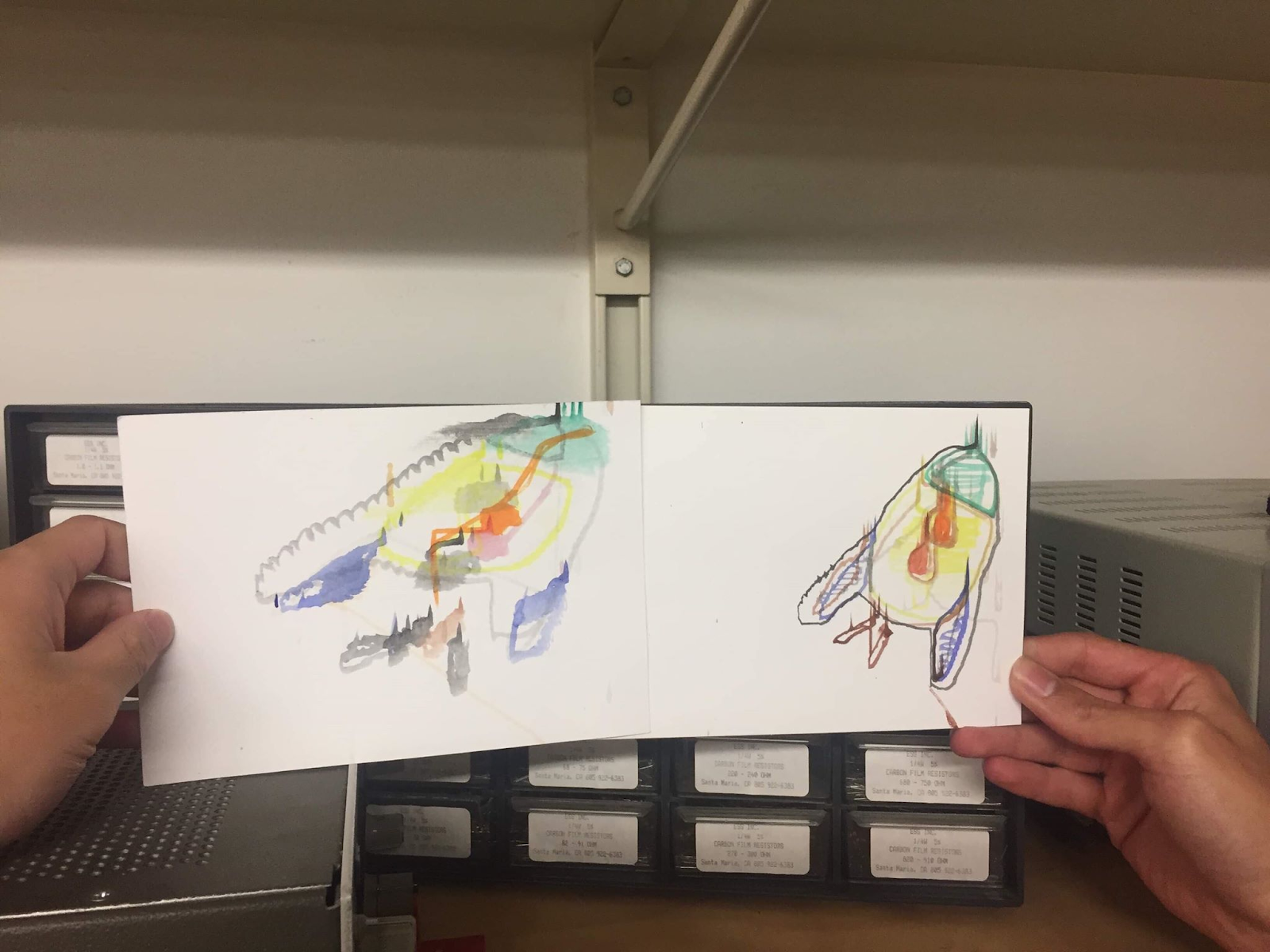

This week, our team approached the completion of our project with numerous improvements, adjustments, and bug fixes. Our robot has significantly improved in nearly all aspects. For example, below is an image of the rocket ship that we were testing with our robot. Under it is a comparison image of what our robot drew last week, on the left, and what it drew this week, on the right.

As the image shows, our robot has made significant improvements in its drawing ability. Several bug fixes and algorithm optimizations has resulted in steadier strokes, a neater image, and a more cohesive final product. In addition, we have created a basic UI for selecting an image and seeing a rendered result, and are preparing videos, images, and other media for use in our public demo.

There are no significant risks remaining with our project, as we have mostly wrapped it up. Some small risks are that the robot still occasionally jams or drifts. We are addressing this by zeroing the gantry often to account for drift and by optimizing metrics and parameters to minimize the motors jamming. Jamming is somewhat inconsistent; there are times when long testing sessions will go without any jamming or issues. During other times, the robot will frequently jam and make errors. Nevertheless, we are doing our best to account for all the known issues of the robot and to ensure our public demo goes as smoothly as possible.

No significant changes were made to the design of the system. Several small additions or adjustments were made, such as testing different power supplies for our robot, adding tubes to allow the gantry to zero in all four corners, and using a thicker brush for broader strokes. No significant changes to our schedule have occurred, and we are rightfully in our last week of work with the completion of our robot on the horizon.