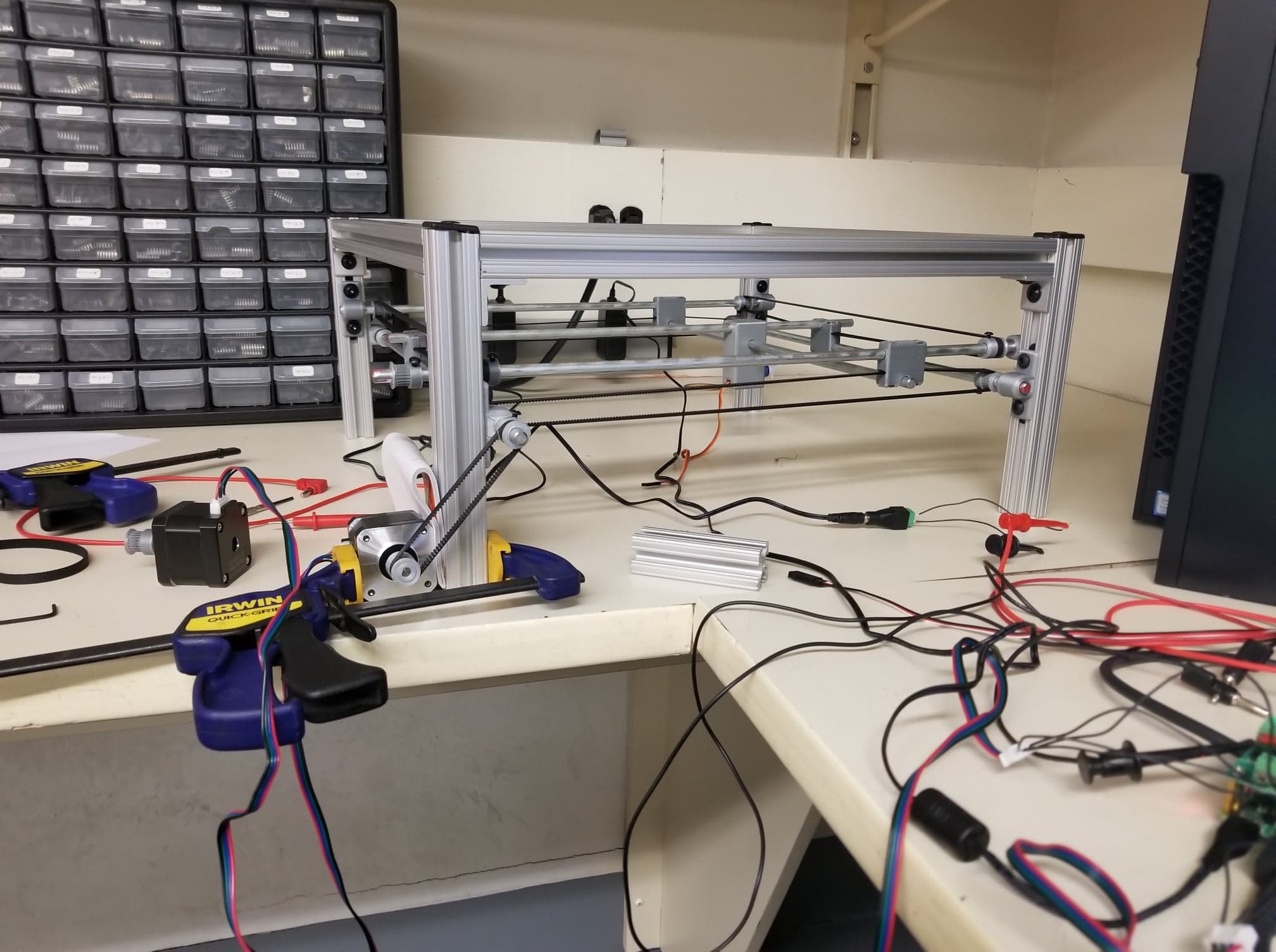

This week, our team made progress in many areas of the project. We are also beginning to put our subsystems together and testing them with each other, and our project as a whole is beginning to take shape. Overall, the team worked this week on preparing for the demo next Monday, which resulted in our progress of being able to trace out basic shapes using our gantry system and motor control software.

There are no new significant risks for our project that we observed this week or that we can foresee occurring. The preliminary tests and experimentation of our prototype gantry is working as we expected with little to no issues. As we continue finalizing our robot and connecting our subsystems together, there still remains the risk that the subsystems do not interact as we expected. However, our careful planning makes this risk very unlikely, and any issues we do encounter can probably be easily dealt due to our planning and design.

No significant changes have been made to our design, and the realization of our robot is going smoothly and as planned. There are no major changes to our schedule, as our progress this week as a team has been on schedule.