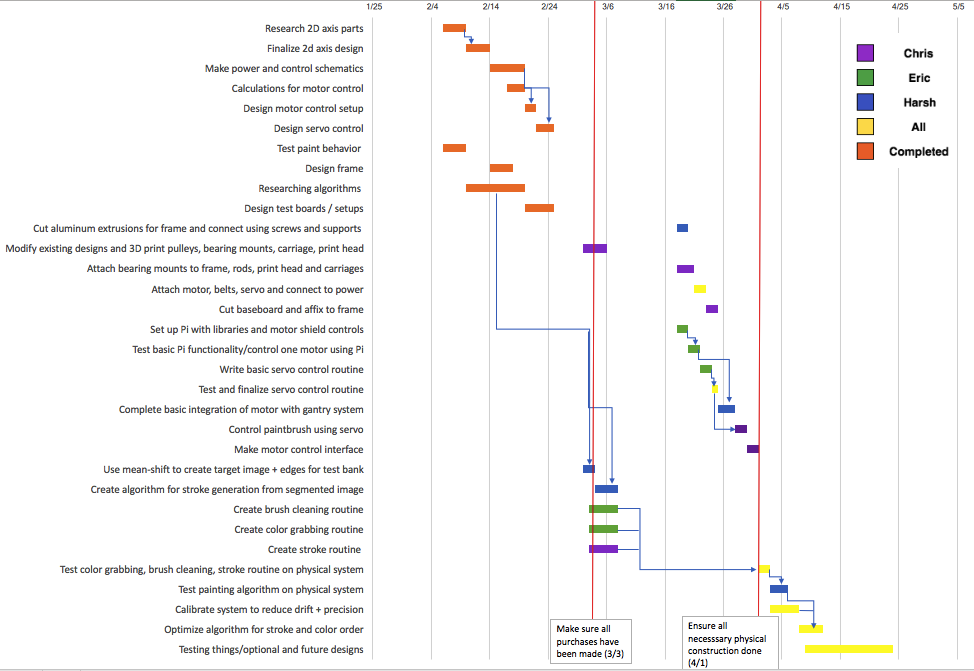

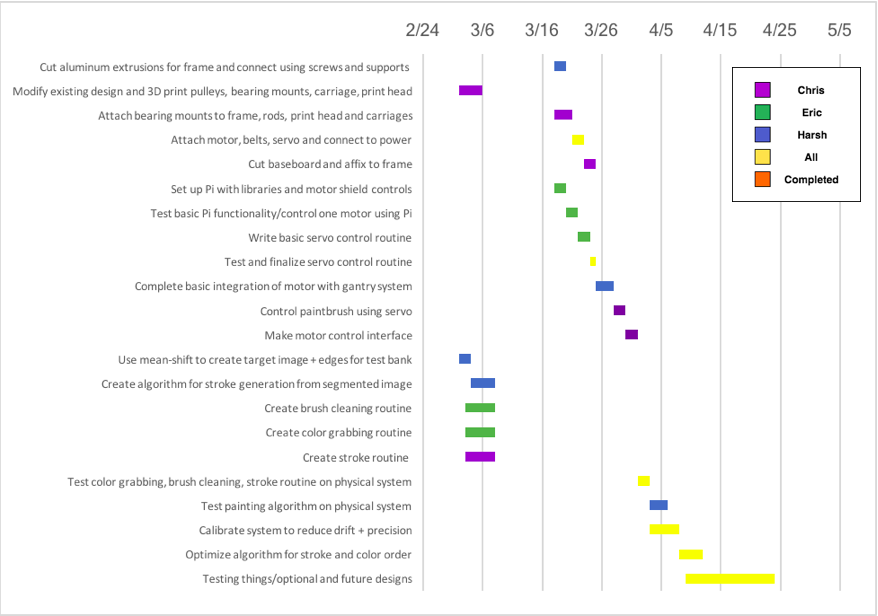

My work this week was mostly focused on contributing to our design document, but outside of this I continued iterating on the 3D part designs and created a template of the routines which need to be developed in python. I printed the initial design of the carriage pat, but due to some size and tolerance issues from printing, the two halves were not able to mate properly. I updated the design to accommodate this but the issue was still present. This issue has been difficult to fix, as each design iteration takes at least a day to verify due to having to wait for the print. Currently, these design issues have set me back slightly and to make up for this I can start printing beta versions of every single part at the start of the next week, to allow for all parts to be finalized and for the full assembly of the gantry to begin.

Additionally I began creating the outline of our software layer and created all of the files we will need to operate the gantry. These files finalize the interface designs between the different components of the software layers and allow us to test each section of the code individually. My contribution to this in the coming weeks will be to develop a simple model replacing the operation of the gantry, which will allow us to test the image processing and stroke generation algorithm.

Overall I have fallen slightly behind on schedule this week, as I have not been able to finalize all of the 3D designs. In the upcoming week I hope to catch up on this, begin assembly of the gantry once the parts arrive, and develop a simple model of the gantry control layer for use in testing the painting algorithms.