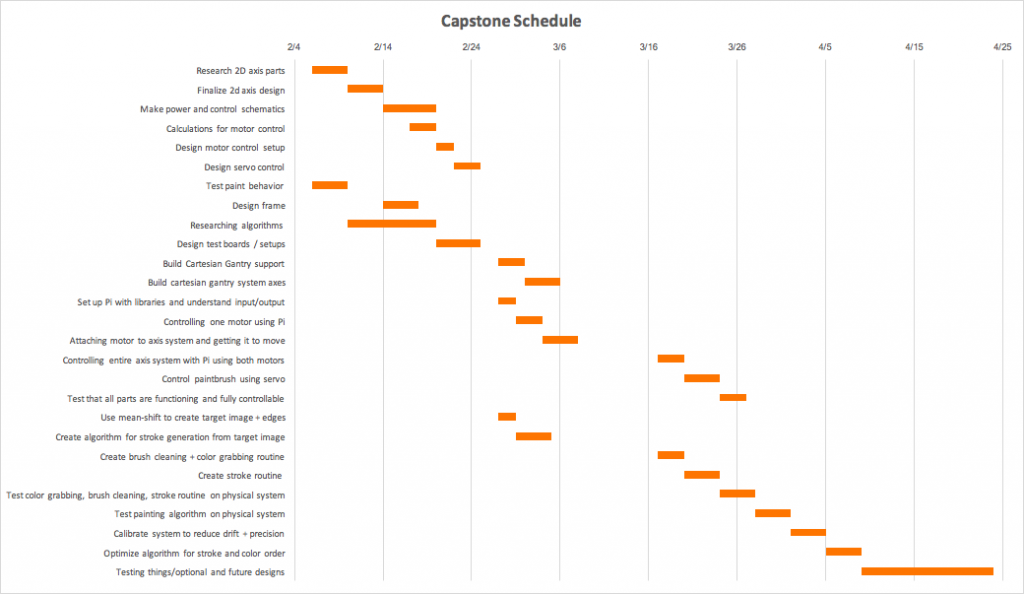

This week, we finalized the design for our 2D gantry system, as well as the frame of the robot. We started ordering many parts, including the Raspberry Pi, the motors, a paint set, and shafts and bearings for the axis system. We worked on our design review presentation, and created several diagrams and schematics for it. In addition, our team met with Professor Aswin Sankaranarayanan to get input on the image processing aspect of our project and discuss our software algorithm.

The most significant risks of our project continue to include the success of our 2D gantry system, which was discussed in last week’s report. We will continue with the plan we have in place, with our backup plans still ready. Once the parts we’ve ordered have arrived, we can begin constructing the system, and adjust our approach and design based on any problems we may encounter during that process. Another risk was brought up once we discussed our project with Professor Sankaranarayanan, who discussed certain difficulties in creating a painting robot. Specifically, he mentioned the main three things to consider would be the clustering algorithm, the color intensity, and the brush width. He gave us some advice in dealing with each issue, and we discussed the potential approaches and solutions amongst our team. Due to the difficulty in some of the image processing considerations, there are risks in how successfully we can translate a digital image to painting. We decided to keep our initial approach, which is based around the mean shift segmentation algorithm. However, if this fails, we can use any of several other clustering algorithms, with k-means being a viable backup. Regarding color intensity and brush width, there are several alterations we could potentially make to our painting procedure if either of these are an issue. We could modify our approach to only deal with silhouettes, only use edge detection and paint the edges of the input image, or just reduce the detail we recreate in our painting. Our painting head is designed so that it can hold pencils, paintbrushes, etc.

No significant changes were made to the existing design of the system, although we did finalize decisions on the hardware component of our project as well as how to power the robot. No changes have occurred to our planned schedule, as we are all on track with our progress.