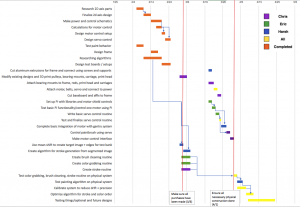

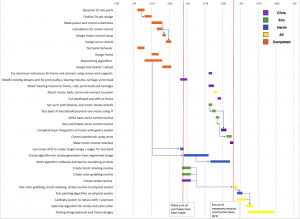

This week, I completed and tested the parallel code that allowed diagonal movement of the painting head which I began working on last week. This code allowed both of our stepper motors to be controlled at once, which was not a default functionality of the motor library that we are using. The code was completed and tested on our system with the motors attached to the gantry, but with the motors being manually held instead of fixed in place. The diagonal movement of the painting head is working fine and as expected. In addition, I also made a few modifications and bug fixes in other areas of our software.

My progress this week is on schedule. With the diagonal painting head movement code complete, the gantry control system is finished. It will continue to be refined in the future as we begin testing the code on the entire robot system, which will happen once we fix our motors in place. In the next week, I will make any refinements, modifications, or bug fixes in the code as necessary as they come up when testing our subsystems and entire project. Besides that, I will help Chris and Harsh with any help they might have in their areas of the project.