Kenny Ramos’s Status update for 22 Feb. 2020:

For this week I began setup work for computer vision and object recognition as well as the rest of the basic RPI toolchains that will be necessary for the project. Most of my time on this was spent setting up RPI, compiling libraries, setting up OpenCV, testing MTP protocols with libgphoto2, setting up cpp interfacing with libgphoto2, and some very annoying RPI quirks.

Compiling linux libraries and setting up RPI specific stuff is pretty mundane so I will go over the library lists needed to compile as well as some preliminary tests that I ran to make sure it responded well.

Libraries Used (for now):

- OpenCV with all extra modules (optical flow and more complex object tracking are both in extra modules)

- Base OpenCV 4.2.0: https://github.com/opencv/opencv/tree/4.2.0

- OpenCV Extra modules: https://github.com/opencv/opencv_contrib

- Libgphoto2: Interfacing library that supports PT(P) and MT(P) protocols

- GTK runtime (included with Raspi and tentative)

Preliminary Tests:

For OpenCV testing is fairly simple since it comes with a set of examples that it is ready to run. Testing should be done later to measure performance. For libgphoto2 I simply tested compatibility with my phone (Galaxy S9 that supports [MTP](https://docs.microsoft.com/en-us/windows/iot-core/connect-your-device/mtp))

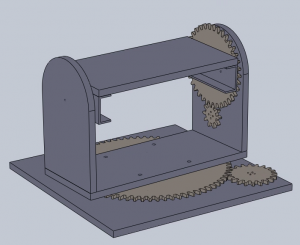

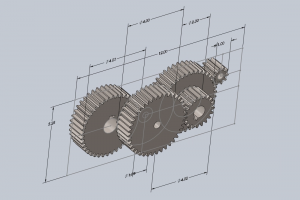

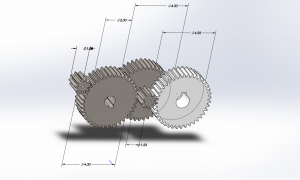

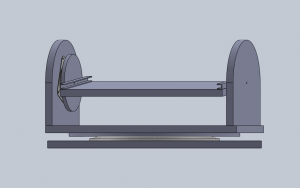

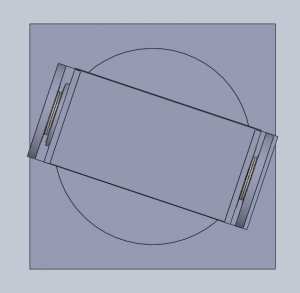

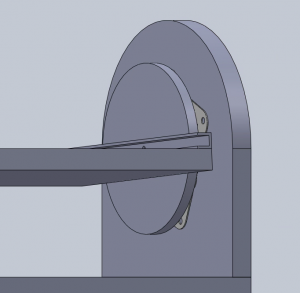

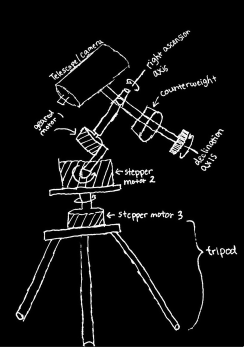

Another task I had to setup this week was trying to figure out how to fabricate parts in the techspark space as well as collaborate with Joy in order to interface the parts I am fabricating with the stand she is working on. I asked around techspark about getting funds or materials for Capstone projects but I think I need to ask the professors and TA’s in more detail next week. Furthermore, the interfacing will probably be held until next week as well.

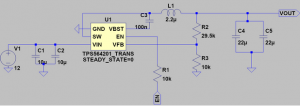

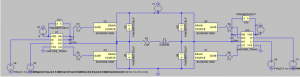

A final task that I planned on starting concretely for this week was getting the testing rigs (mainly the star projector) started. I finalized the block diagram and overall plan but I wasn’t able to start the modeling and simulation portion as of yet due to delays from setting up software as well as working on design review presentations. I plan to make up most of this lag next week assuming that our Design Review presentation is rugged enough to make the Design review report easier to finalize. If this is not the case I might have to put in some time towards the end of next week to try to get this done before spring break.

For risks I don’t foresee any more structural/implementation problems that could arise (other than the ones discussed last week). The only new risks are operational and managerial ones in the forms of delay and lack of sync that should get handled by more rigorous attention to checkpoints set by our schedule.

For next week the plan is to flesh out the testing rig in solidworks and finally get things on the compensator side fabricated so that I can start integration with other team members. With the RPI setup and working properly that can go into the backburner for next week in the interest of finalizing fabrication.