Addressing some of the pressing design oriented feedback received:

Some of the feedback we received dealt with how much fidelity the star mount could simulate actual starlight. To address this we plan to discuss the target of each subsystem test. For one, the star simulating mount does not serve the purpose of simulating actual star-light but rather the movement of stars. Since the capture device is out of scope we plan to specify certain restrictions for how much contrast there should be between an object and the “background” (space) in order to allow for accurate “object identification” (tokenization really). This threshold will be tested with generated offsets of real captures taken with a typical entry level capture device (~$700 DSLR cameras [Canon T7i or Nikon D5600]) with 55mm lenses). However, since this is out of scope our stand works with the assumption that these captures meet these metrics [A badly taken capture, for example a long exposure shot of a sodium street lamp, would not meet this].

The rest of the feedback ran along the lines of too little specification in the design presentation as well as some doubts when it comes to competitive analysis. These will all be reflected in the final draft of our design review.

Risks:

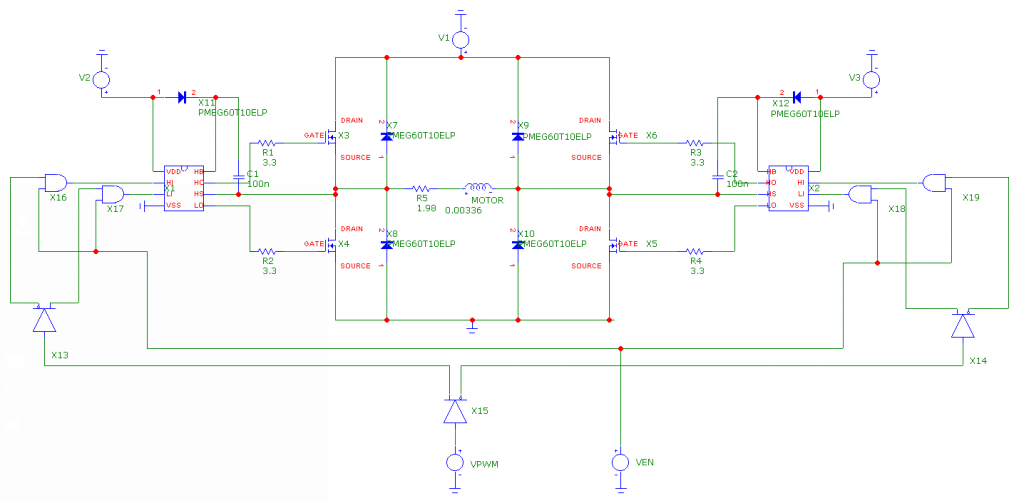

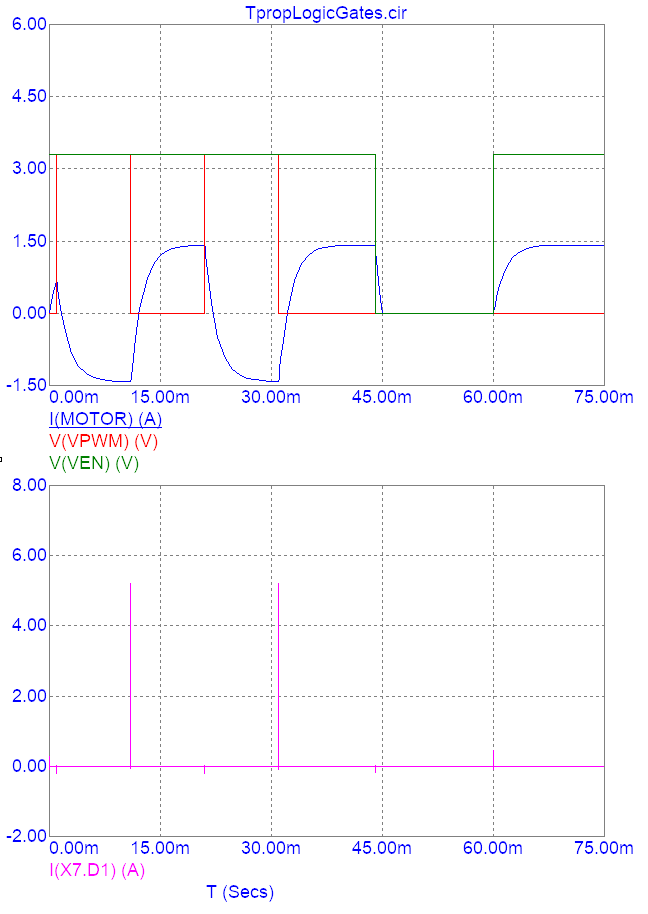

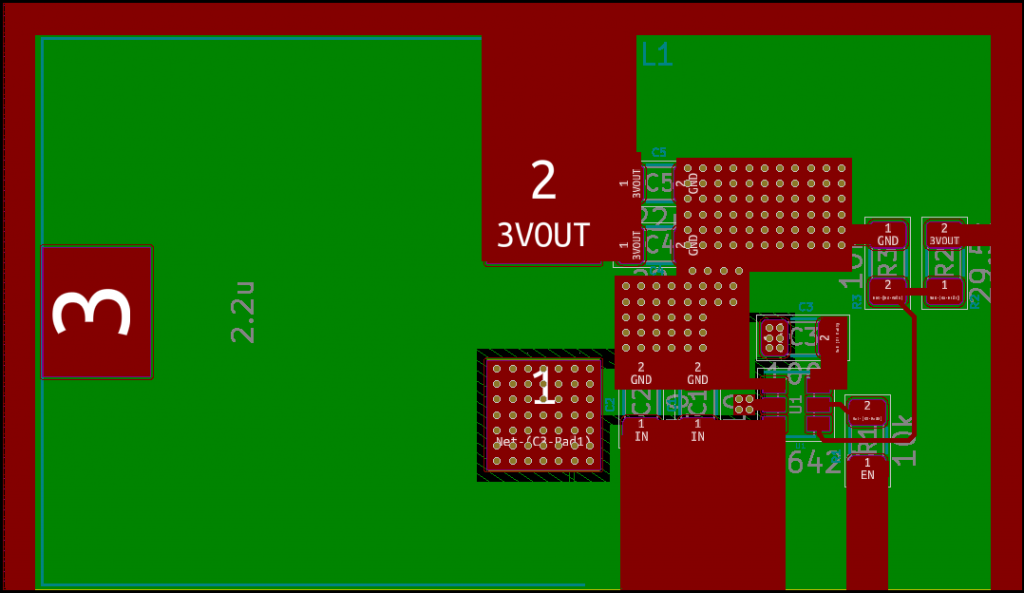

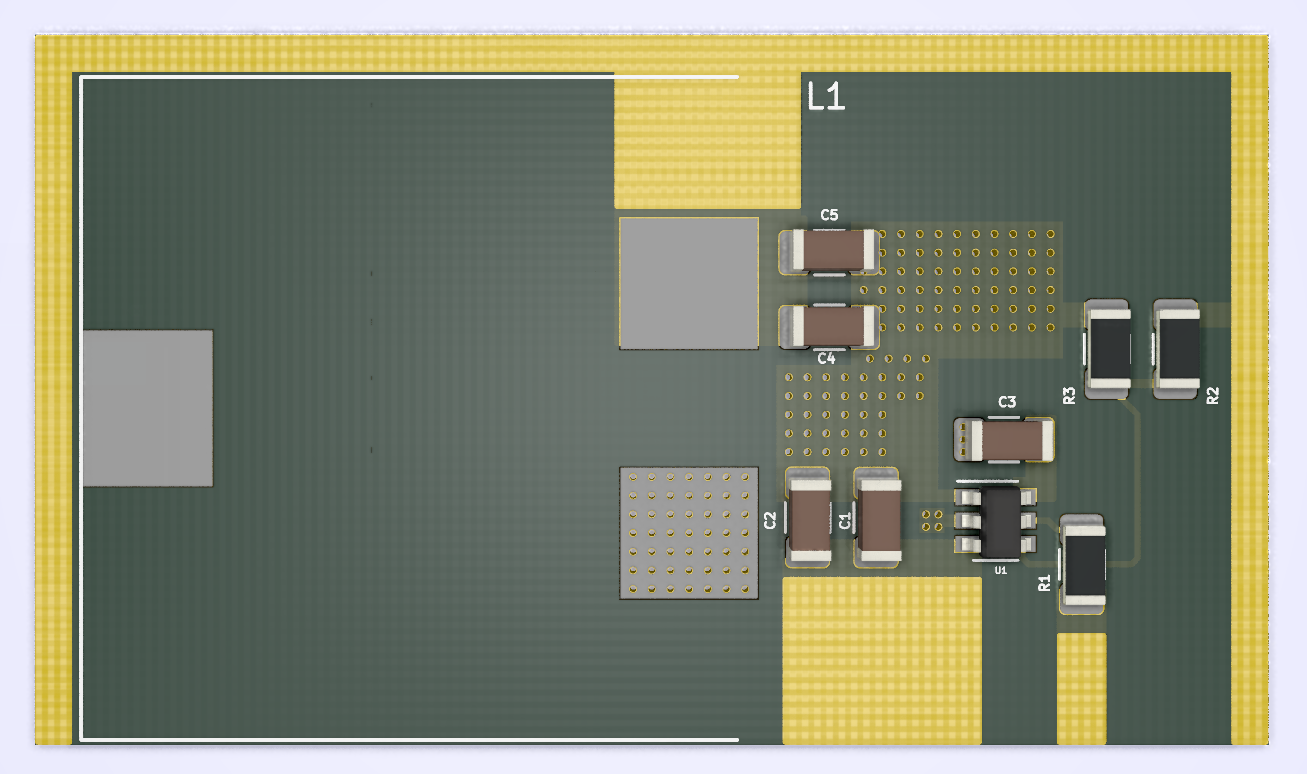

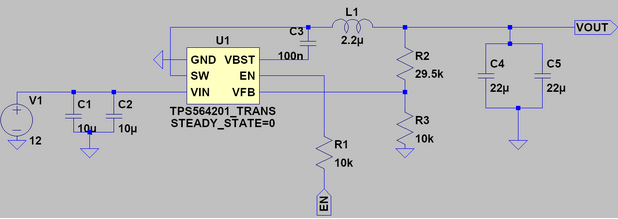

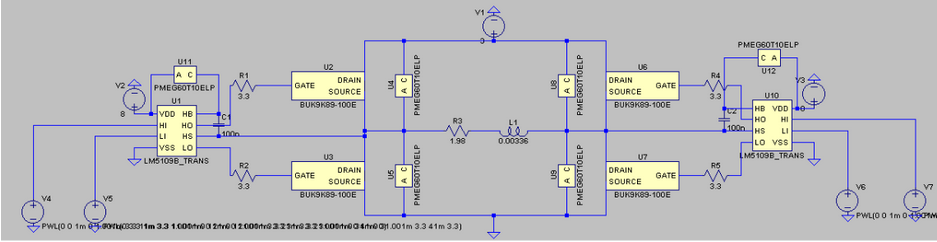

There is a risk that Yuyi won’t be able to work much on the circuitry and layout associated with the test setup this week, as CMU’s ECE Open House is scheduled from Tuesday to Thursday of this week. This could push our schedule back because this will leave Kenny to work individually on the circuit design for the laser drivers/motor drivers composing our project’s test setup. Fortunately, the impact of this is unlikely to jeopardize our project. Work on the CV and physical mount is still progressing and the test setup will not be needed until such is completed. Therefore, a contingency plan isn’t really required for this.

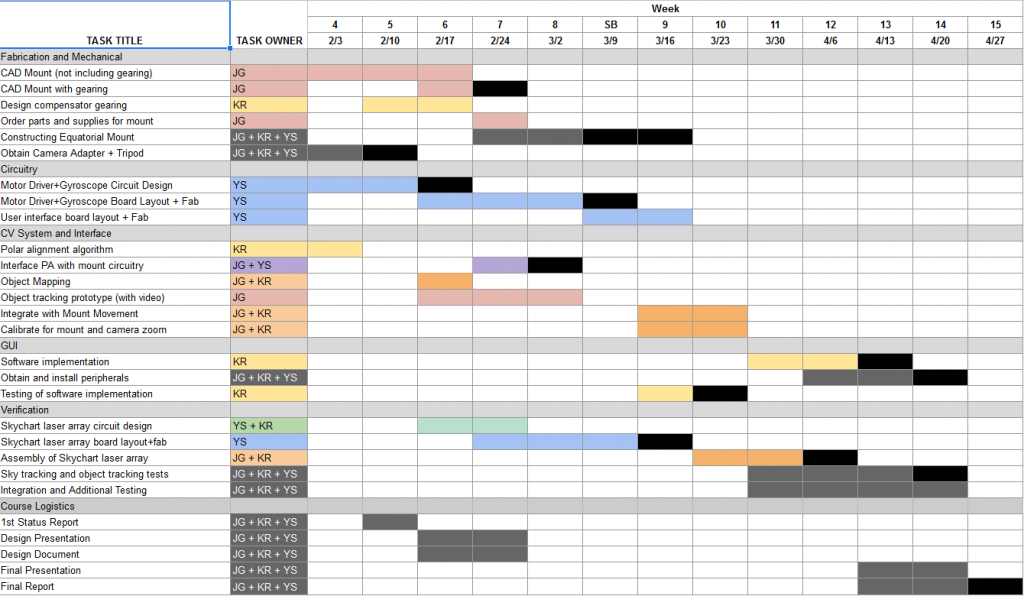

Thus far, we haven’t had a need to make changes to the system’s existing design. However, we intend to push the layout and fabrication of the user interface board of our project to the week of Spring Break. The task will then last until Week 9, when our team will begin integrating the CV with the mount’s motor system. The new Gantt chart is as follows: