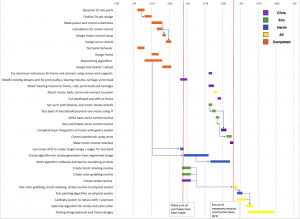

This week I continued working on the construction of the base board. Due to carnival and our parts for attaching the motors to the board not arriving, I was not able to entirely finish construction but was able to complete the areas for the palette and the attachment mechanism for the paper for painting on. This involved making some slight modifications to our design, as we originally planned on having a small cut-out for the paper to be placed in, but after some work on the board we realized that this would be more difficult to implement. Our design now uses screws with nuts and washers to tighten the paper to the page. This design has been completed and we were able to test operation of the full gantry with this design and the palette and the paper are positioned well and solid enough that contact with the brush will not disrupt the system.

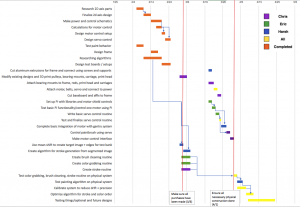

Overall this week I remained mostly on schedule, although early next week I should finish construction of the base board entirely so that we may begin the more extensive tests of our gantry system. With what we have now, we were able to test and get diagonal movement of the head working. My goals for next week are to complete the base board entirely early on, and work with Eric to test the gantry control layer on the completed gantry system. I foresee there being some issues in this area, so we can begin working to resolve this and modify how our motors are attached as necessary to allow for consistent control of the paint head. Additionally, now that the positioning of the palette and the paper has been set in the board we can take measurements of these locations to begin programming these fixed locations into our system.