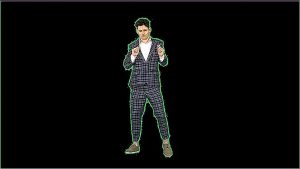

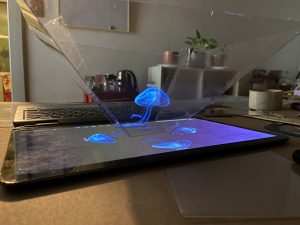

Over the past week, I worked on final logistics. As planned, I helped finish up the final presentation at the beginning of the week, fixing up slides so that they had less text and were more readable as well as more visually appealing with pictures of the pyramid. I also checked through the final presentation slides to affirm the content and helped Breyden shoot some footage for the final video and perform testing of our system. A link to the presentation slides can also now be found on our website here.

At the end of the week, I worked with Breyden on an outline for our final video, determining how long we will speak throughout different sections. I also put together some slides and recorded audio for the sections of the video discussing the background removal algorithm, display, and pyramid. Over the next few days, I plan to record more footage of our project with Breyden’s help, in order to have B-rolls so that Jullia can edit together our final video. Our goal is to get good footage of stationary and moving objects inside the studio and also demonstrate the user experience of using our HoloPyramid project. Once this is done, we will upload the final video, make a poster presentation, and finish up our final report. My progress is on schedule, and I am on track to finish our project over the next week. As this is the last status report, there are exist no further deliverables.