This week I worked on:

– Observing and commenting on other team’s projects. For Monday and Wednesday 10:30 to 12:20, I have observed other teams’ presentations and gave feedbacks regarding their content and their presentation skills.

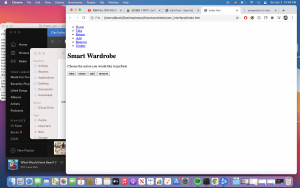

– Preparing and Presenting our team’s presentation. Our team has conducted our presentation on Wednesday, and in order to successfully deliver our presentation content to our peers, TAs, and professors, I have practiced my oral presentation skills for 5 iterations.

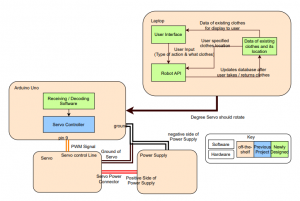

– Receiving feedbacks and rescoping our project, specifically on the hardware side. We have received quite a bit of criticism of our initial design which involved a robot arm. This was due to the fact that there are too many components required and required us to do a CAD design, which none of the team members have experience. Thus, instead of implementing a robot arm, our team members have decided to do a rotating clothes hanging bar.

– Deciding on alternative hardware solutions besides the robot arm. This new hardware design will not require any CAD design but rather can be accomplished by mainly a servo that can rotate 360 degrees. Additionally, we have decided that we would need parts such as turntable bearing, metal-metal epoxy.

Next week I will work on:

– Choosing the exact parts of our design. We have decided that we would need certain parts such as turntable bearing, metal-metal epoxy, metal ring, servo, controller, and a base, and next week, we will actually finalize the exact parts, get confirmed by TAs and the professor, and order the parts.

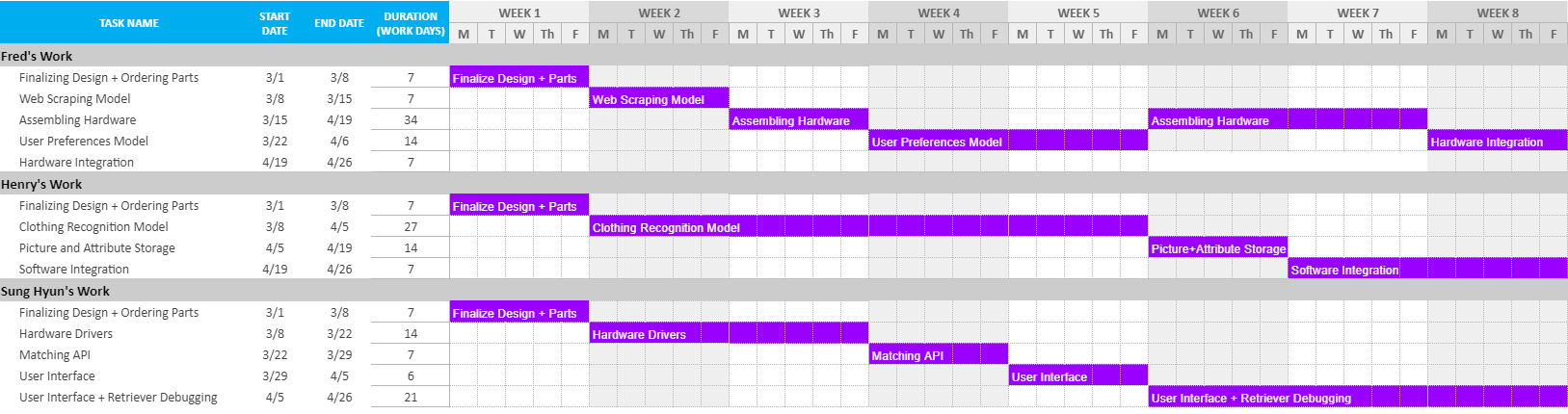

– figuring out how to communicate with the servo. According to the Ghant chart, I will be writing the drivers. One option to communicate with the servo is an Arduino, but this might not be allowed, so I’m planning to ask first if using Arduino is allowed, and if not, will look for alternative options to write drivers for the servo.

– preparing for the design presentation. As a team, we will work on creating the presentation slides and help Henry prepare for the presentation.