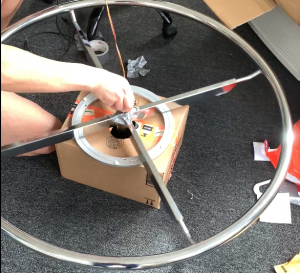

This week we assembled most of our hardware parts by laser cutting all the wood pieces. As a team, our biggest focus was how to connect the two gears with precision, and ensuring that the gear rotating the hanger is the absolute center of rotation. In order to achieve this we have Laser cut alignment wood with a hole in the middle because 3D printing will eliminate human error of guessing where the center of the servo is. In addition, we have tested the metal-metal epoxy because this attachment is used between servo and smaller gear and is also used between clothes rack and bigger gear. After waiting for an entire night, we have ensured that it won’t fall off easily, and will hold when we use the servo to rotate the hanger. In addition, this week we have debugged many issues we had with the software so now all we need to do as a group would be debugging the interface between software and hardware, and do some actual function testing for our entire system as a whole.

Getting closer to assembling the entire hardware, we have identified a couple of potential risk factors. One of them would be our design relies on metal-metal epoxy to attach the gears to the servo and the hanger. It was strong enough to stay attached when we had no clothes on, but it might not be able to hold when we rotate with clothes on since the surface area of the gear is not that big. We will mitigate this risk by validating our attachment with clothes on tomorrow, and if this doesn’t work, we might want to get bigger gears to increase the attachment surface area.

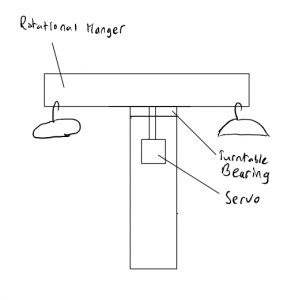

These are the pictures of some parts of our hardware