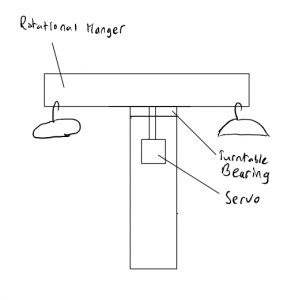

After giving our presentation we realized that our hardware side had issues in implementation. With the help of our advisors we brainstormed a new idea to use a rotational hanger system attached to a base, link goes more in depth. (https://docs.google.com/document/d/1n_NDpZC0ni2qttofl1uJjUk9jUlInqgykfnHyiBxZws/edit?usp=sharing)

After creating a new design we fixed design requirements for weight and used that to calculate the torque that we would need. We also looked into what kind of motors would fit our precision and strength requirements. We ended up choosing servos because they fit those requirements. Although this did set us back in our schedule a few days we have also removed the CAD elements of our project which should allow the schedule to keep going as planned.

One risk we see moving forward is receiving negative feedback about the design and having to redesign it. However, from the communication we have had so far with our advisors it looks like we have met their requirements and are confident about this design.

Another risk is in our calculations to determine friction. We found friction coefficients for turntable bearings online but not for the models that we could realistically purchase. In order to mitigate this risk we added leeway in our calculations and are looking for a servo stronger than the minimum requirement.