This week I have:

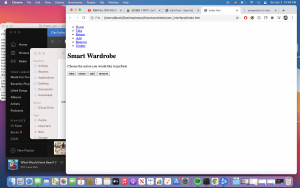

– Fixed major bug of user interface and database

– The rack should rotate at “add” page and then the database should be updated at “update_add” page. This is because we don’t want the database to be updated before the user retrieves clothes, because if the database is updated before the rotation, and the system is reset before the user gets the clothes, there will be a disparity between the database and the clothes that are actually hung on the rack

– In order to fix this, we have implemented an update_add page, where the user will insert its preference and press done when the user actually retrieves the clothes.

– Another bug that we noticed was the integration between retriever API and the hardware

– When we tell the servo to rotate to a certain angle, it will rotate with maximum speed / acceleration that would lead to our hardware to break

– In order to mitigate this issue, I have changed the retriever API to know its current location and the destination location and turn 6 degrees of angle at a time, to minimize acceleration / deceleration since f=ma. Simply put, we will stop the servo intentionally before it accelerates too much.

– In addition, I have started the integration between user interface and all the other APIs because the functions in user interface will be the one calling other APIs

– Matching API for example was in a folder, and wasn’t able to import the database, so I have redirected / reorganized the directories.

Next week I will:

– Test the hardware to make sure that it won’t fall apart when we rotate the system by 6 degrees at a time. If this is not enough, we will probably have to find a more sturdy attachment method between the gear and servo and the other gear and the rotating rack.

– Finish integrating between multiple APIs and do a live demo with all the clothes, checking for any new unseen bugs