The past 2 weeks I have:

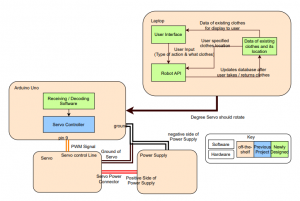

– Written the design report for the parts which I am responsible for: Matching API, Retriever API, and User interface.

– Worked on the specific logic for the user interface (which api / function calls each user input would create)

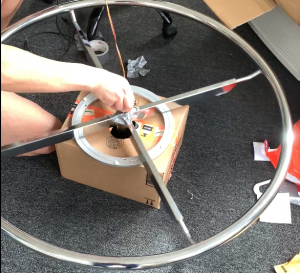

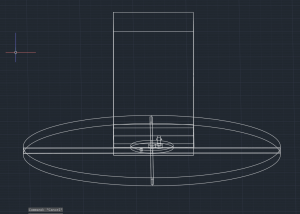

– Worked mostly on the verification of the servo. After doing the testing, we realized that our current Servo does not work for multiple reasons.

– First, our servo is simply not strong enough to rotate our hanger. After setting up the prototype, with the servo just rotating the hanger with no clothes on, the hanger wasn’t spinning. We believe this is due to the fact that our Lazy Susan was simply not smooth enough, so our estimation of the static coefficient is not enough.

– Second, we can’t designate the servo to rotate to a specific rotation angle. For a servo with a fixed rotation angle (ex) the 180 degrees servo, we can simply call

angle = 180;

servo_test.write(angle);

and this code would simply rotate to the angle.

However the servo that we currently have is a 360 degrees continuous rotation servo that if we input a constant pwm signal, it would just continuously rotate. In order to fix this issue, I have implemented a timer so that I can start and stop sending pwm signals, but the issue of this will be that the error would accumulate. Thus after doing validations, we have decided to buy a 270 fixed rotation servo, but have the gear ratio to be 3:4 so that using the gear, our servo would be able to rotate the hanger 360 degrees.

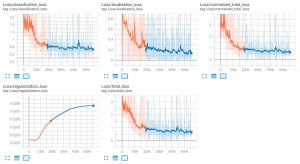

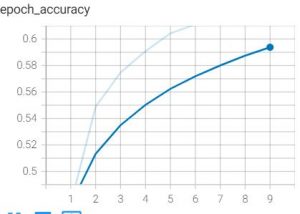

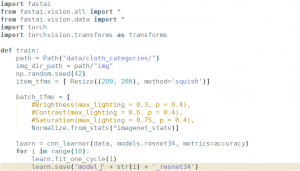

– Assuming that the new servo would work accordingly, I have rewritten the retriever API

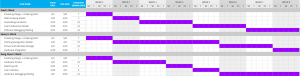

– Due to this issue, I am slightly behind on schedule

Next week I will work on:

– catching up with our ghant chart.

– Finish writing the retriever API, assuming that the behavior would be identical to the 180 degrees servo that I have used for a different class

– start working on the matching API