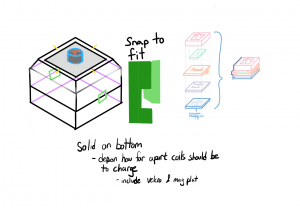

Currently the risks are the same from last week, but much more mitigated now. We have a 3D design of the housing and can confirm the dimensions in the following week when we have fully assembled keys to see how much room we can have and shave down. Currently the dimensions are 25x25x23 mm^3 (w x l x h), and this is with most likely more leeway than is needed. Since it appears we can have 3D housing finished soon, that worry is one less. The programming software unfortunately cannot be started until we have working prototype of the whole system set up, however with the progress of the receiver and BLE boards, we should be reaching that goal soon.

The wireless charging kits came this week so that we may begin working on the proof of concept next week as well. This will be helpful in determining on how fast the charging will be once we have made our adjustments.

No significant changes have been made since last update.

Our schedule is on track as we were able to do 3D housing this week.

New tools: Using Solid Works instead of Autodesk due to more familiarity and no need to import the BLE footprint. Solder iron to solder the keys together with the hot swap boards.

Currently with 4 keys connecting to one another, the receiver acting as a keyboard, 2 key modules assembled, and solid works file of the 3D housing(forgot to take screenshot), we have made good progress.