List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

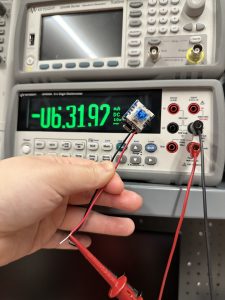

The unit tests done were the testing of Battery Life, Stability, Size, Reliability, Hot-Swappability, and Wireless Connectivity. Battery life was tested by measuring the current draw over a period of time, and determining the average active and passive power draw. Stability was measured by taking a video of the key being pressed while secured to the plate, and measuring the side to side wobble recorded from the video. The size was measured with calipers. The reliability was measured by pressing each key 10 times and ensuring that all 10 keypresses were received. We found that pressing the keys very quickly in this test would cause issues with key presses not registering, so changes to the receiver code were made such that these rapid keypresses would still be registered.

Overall system tests carried out were Layout Freedom, Weight, and Latency. We tested the layout freedom by moving the 16 keys around in various positions and ensuring that all of them were still able to transmit a keypress back to the receiver. We tested the weight by putting all 16 keys and baseplate onto a scale, and recording the resulting weight. No changes were made as a result of any of these tests.

Testing images found in final presentation.

Currently, the most significant risk is that we will not have time to finish the various assignments on time, as we all have finals and other assignments due the same week. However, if we manage our time well, we should be able to finish everything on time.

No updates to the schedule or design requirements have been made.