What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

The most significant risks that could jeopardize the success of the project are getting the vibrations motors operational. This means we need to come up with a way for the current output from the servo driver to increase. The risks being managed are reassigning tasks to research either a solution to increase current from the PWM pin, or to create a custom PCB to accomplish the task.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

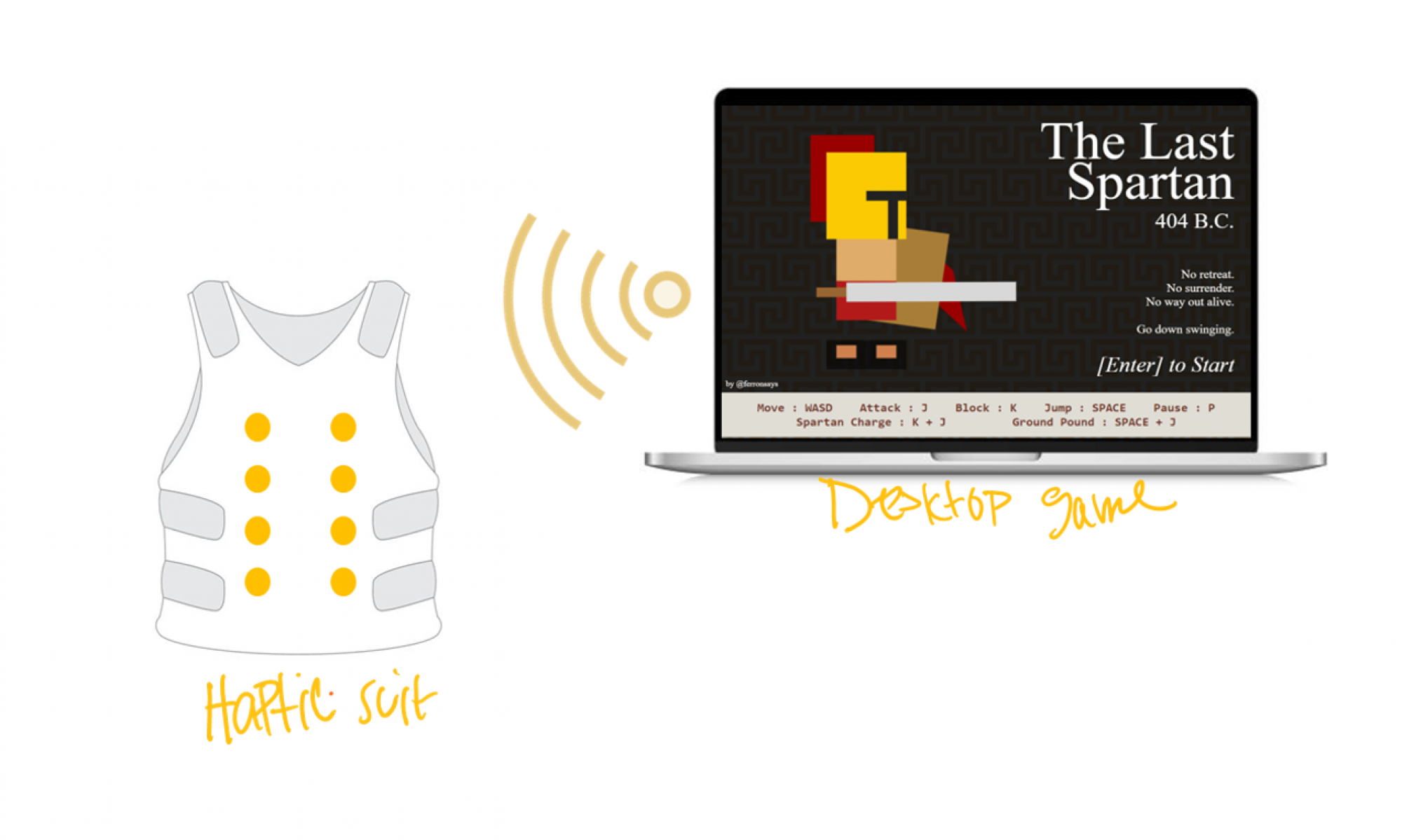

Additions made to the existing system are adding an extra block between each servo driver output and a vibration motor. This was necessary to ensure the motors will have enough haptic feedback for the gamers to feel. This will increase the cost of the system. A fully custom PCB that connects to the Arduino I2C and outputs PWM on two pins would have been better, however with little experience with creating custom PCB, figuring out custom I2C communication protocols on the PCB may be a bit too much for a first project.

Provide an updated schedule if changes have occurred.

If the PCB is designed and sent out before Spring break, it can be tested when we get back.

This is also the place to put some photos of your progress or to brag about component you got working.

We’ve finalized where on the body the motors should go. We also got our vest in and, despite it coming in a small size when we wanted a larger size, it will work perfectly for the haptic suit. We found that turning it inside out will allow the RGB lights to shine through the material.

Enumerate how you have adjusted your team work assignments to fill in gaps related to either new design challenges or team shortfalls (e.g. a team member missing a deadline).

We have adjusted the team work assignments by compressing some of our larger milestone projects (like programming a motor algorithm) to make space for getting a necessary custom PCB built.