What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

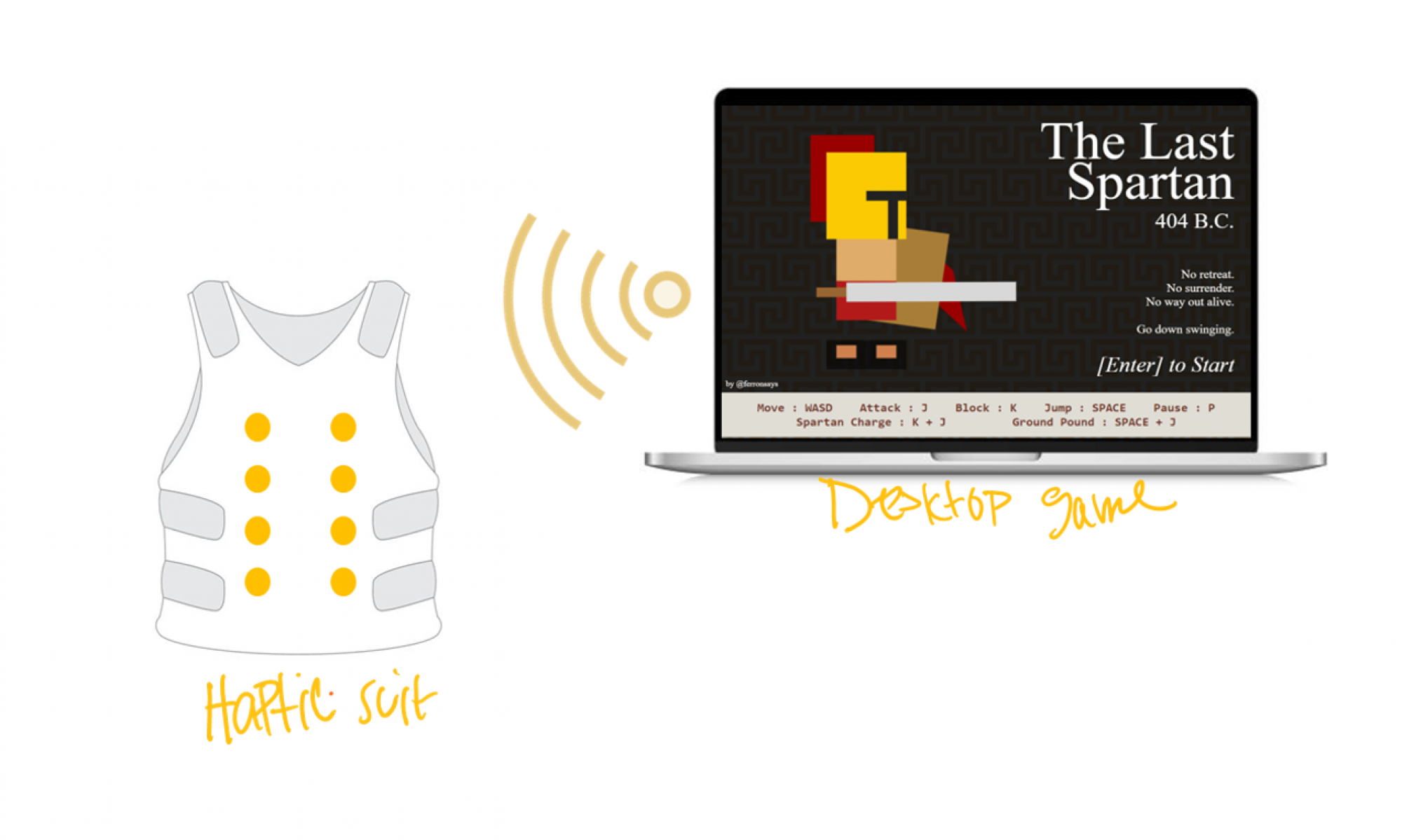

This week we have successfully managed to incorporate the rest of our motors into the back of the vest. On the contrary, we still need to make both the integration of our hardware and software components more reliable. This involves us having to parallelize our motor and light code which we plan to accomplish this weekend. Moreover, we aspire to establish wireless interfacing between The Last Spartan game and the vest (post MVP).

Another risk we are preparing a contingency plan for are wiring issues. We tried to mitigate this risk by using ribbon cable to improve clarity of cabling, making debugging far easier.

While improving upon our hardware and software integration we will simultaneously be working on our poster and project video this week. The risk here lies in our time management. We plan to delegate different tasks amongst ourselves to help maximize our productivity and minimize any risk associated with running out of time.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

The block diagram was changed last week to include the PCBs. Some minor motor system numbers were changed to fit with the actual wiring of the vest.

We also pivoted from using the Puppeteer library to track the remaining three in-game actions of low health, getting hit by a small enemy and getting hit by a large enemy within the past week. The problem with this library lies in the fact that it didn’t allow us to customize the game as per our user and design requirements. It has since been eliminated from our existing design of our system.

List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

Hardware

- Recheck that each motor system works individually

- Motor responses are correct

- Verify that moving vest doesn’t disturb motor systems

- Verify that the light systems have correct response

- Check that implemented code for last two motor systems goes off with other motor code

Software

- Test that the Node JS server prints out the data we want it to relay

- Verify that the Node JS server can relay data from a generic website

- Check whether the Node JS server can send correct data to control a single motor circuit

- Validate that the Node JS server can send the information generated by one in-game action, namely forceful jump

- Validate that the Node JS server can send the information generated by all the in-game actions, namely forceful jump, low health, getting hit by a small enemy and getting hit by a large enemy

- Test that the latency of our system lies under 100 ms

- Verify that our precedence algorithm correctly dictates the outputs we want to see in the chronology of the importance of events

Implementation

- Verify that motors systems and lights go off at the same time

- Try the software 10x times to determine reliability

- Try the software on 2+ laptops to determine reliability

- Have 10 people play the game to gain more user data, feedback, and check the vest is operating correctly

Provide an updated schedule if changes have occurred.

We have attached our updated schedule in this link. We are working to parallelize our motors and lights as well as achieve wireless interfacing between the game and vest (post MVP).

This is also the place to put some photos of your progress or to brag about a component you got working.

Link to image of the PCBs at the back of the suit