What did you personally accomplish this week on the project? Give files or photos that demonstrate your progress. Prove to the reader that you put sufficient effort into the project over the course of the week (12+ hours).

My team and I attended Wednesday’s Ethics Lecture and meticulously made notes on the ethical considerations brought up by our peers within our Pods discussion. We do plan to incorporate the feedback we received to our existing design as expressed within our Team Status Report.

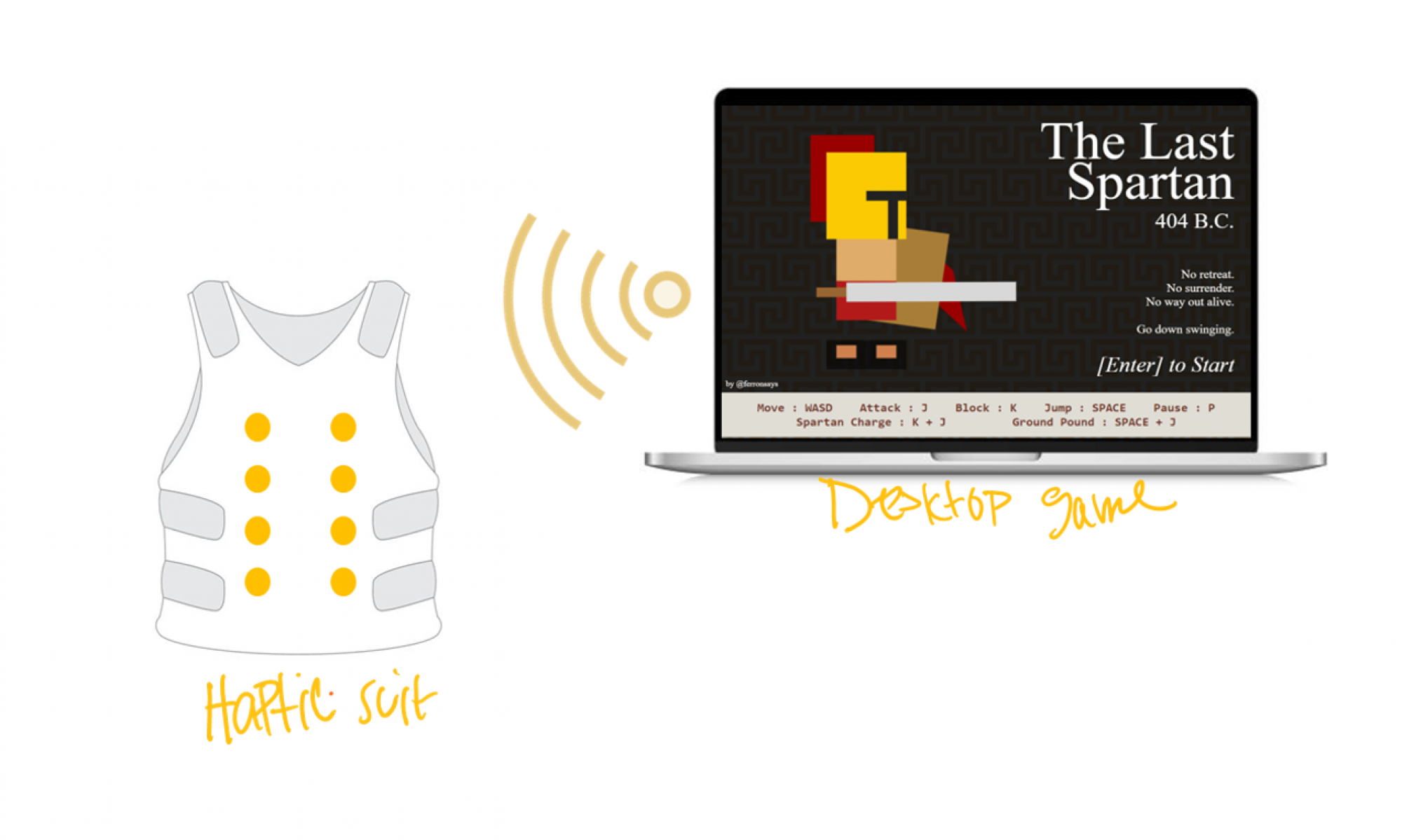

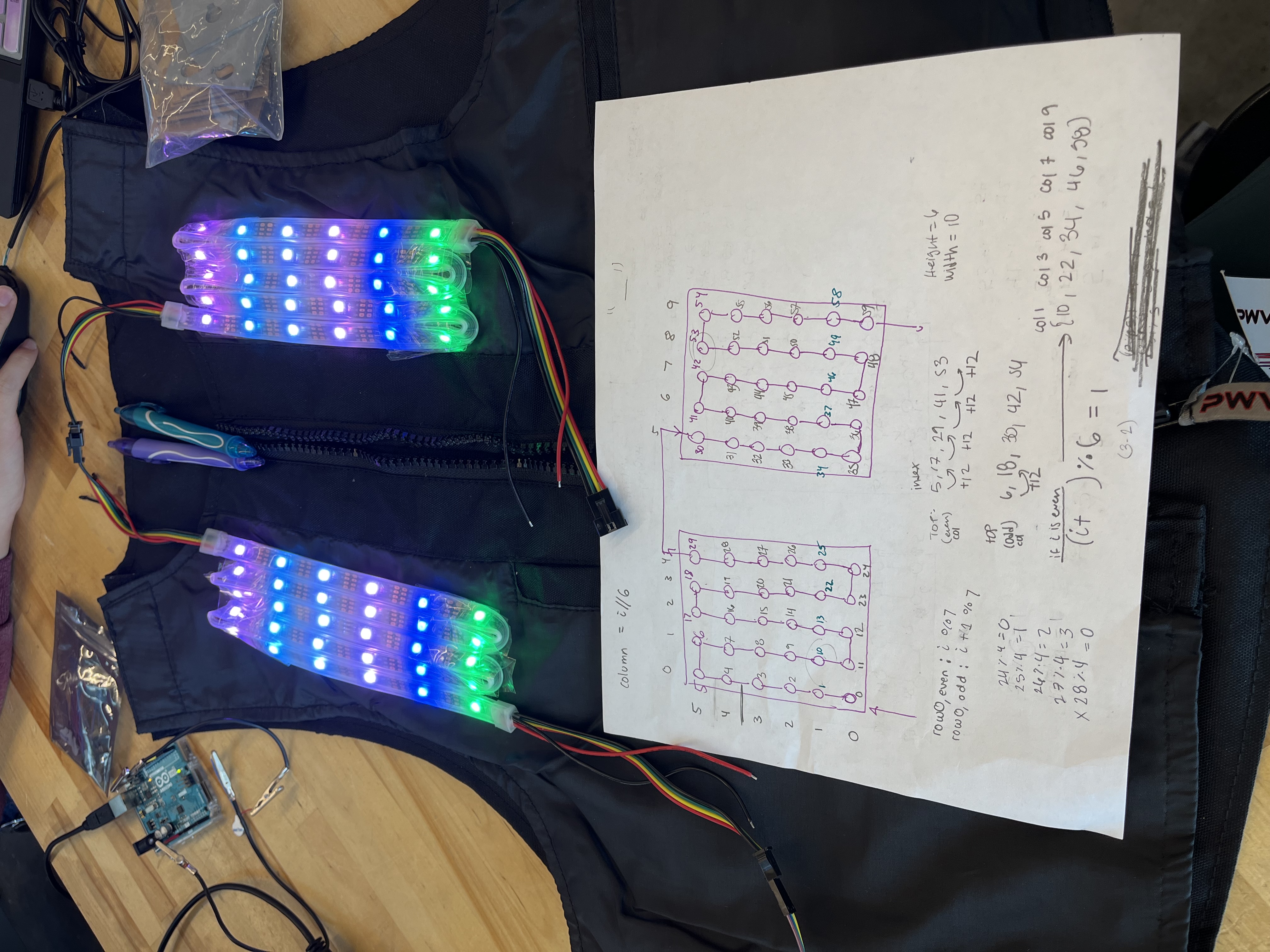

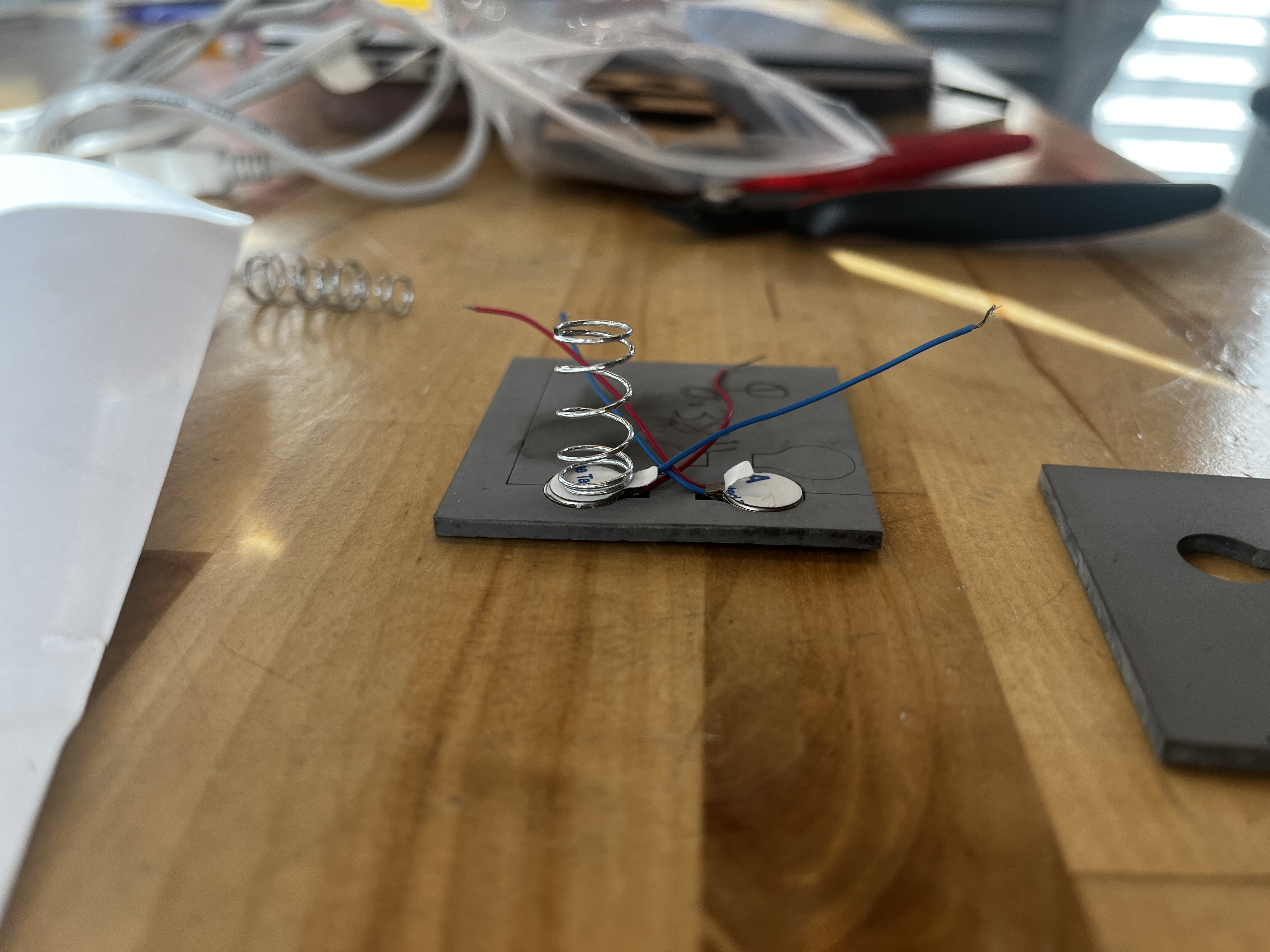

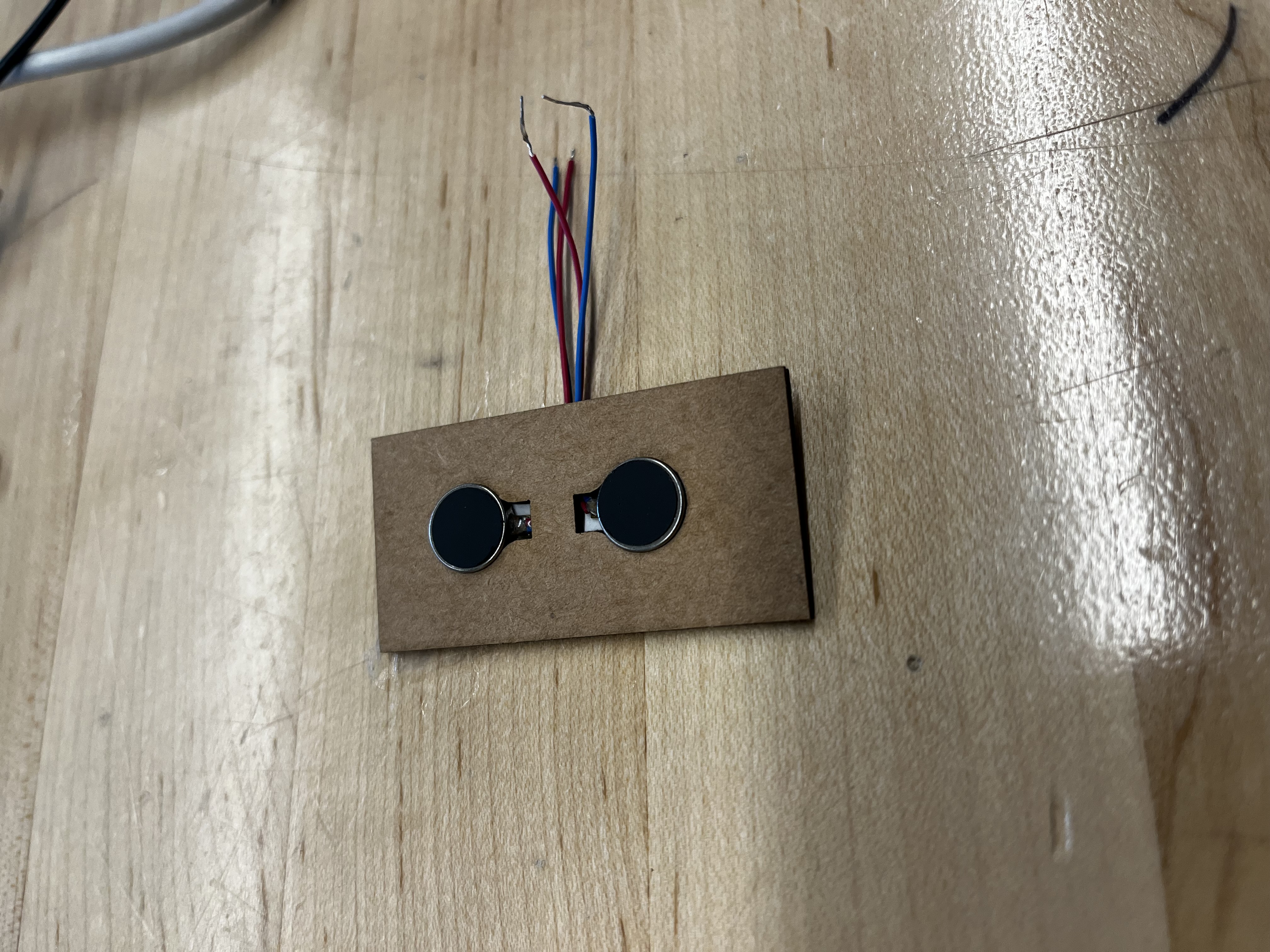

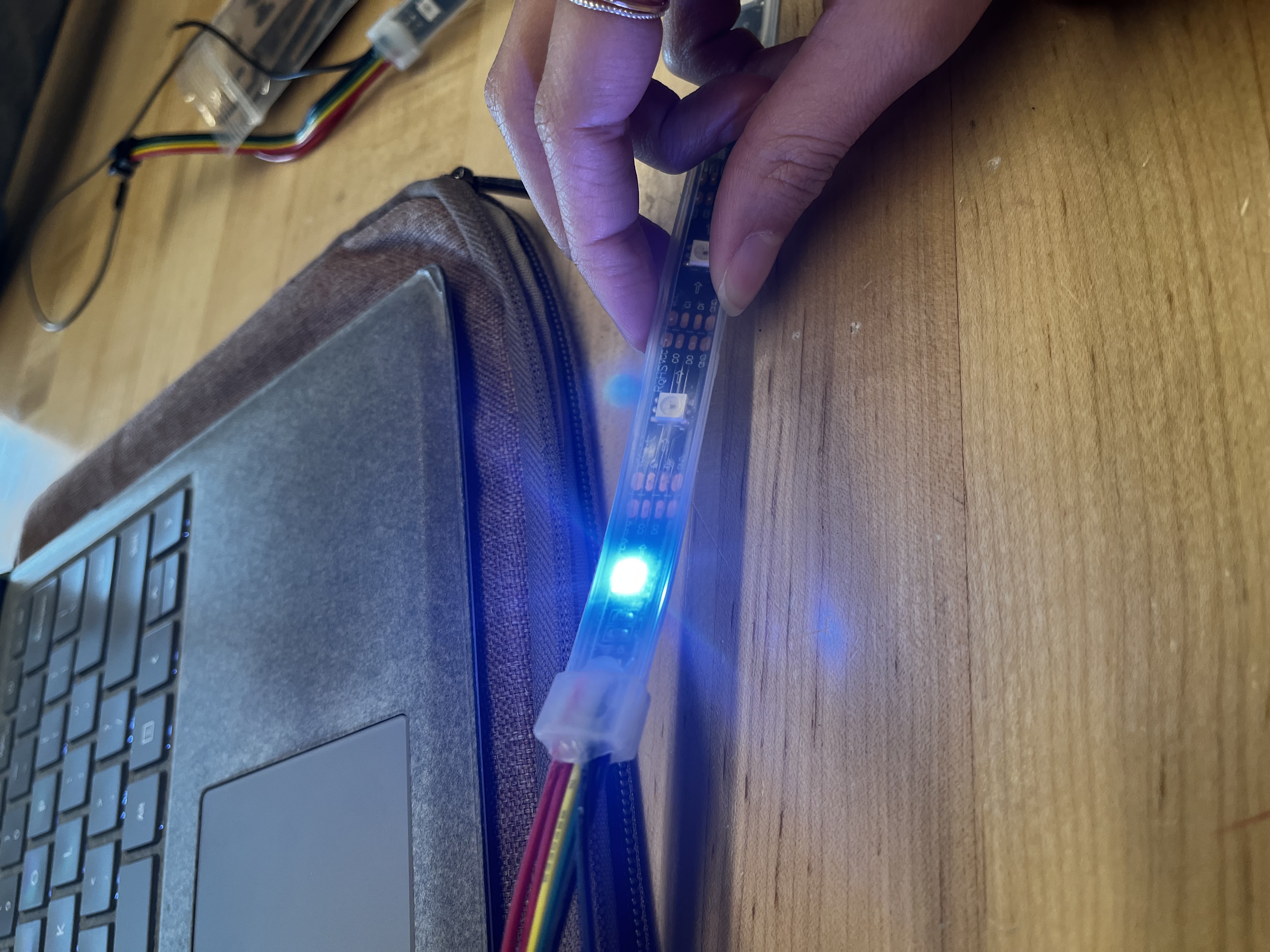

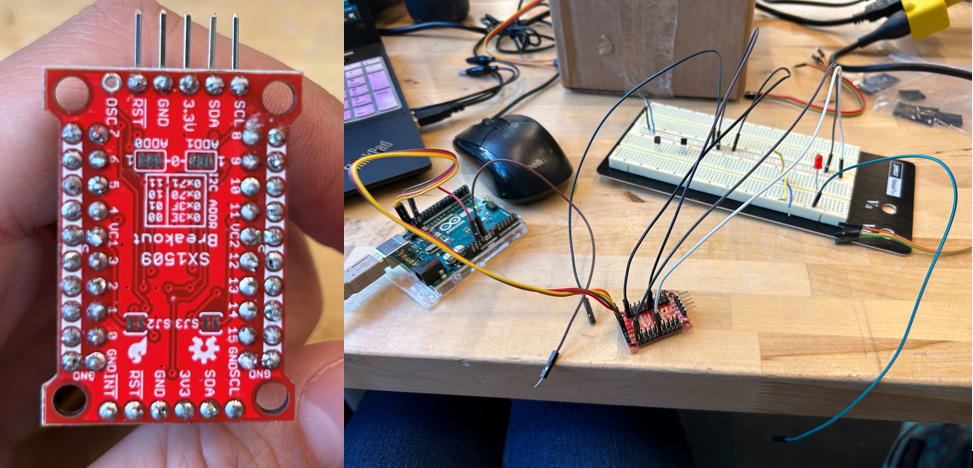

This week has been particularly productive, in that I was able to complete both of my planned deliverables while also using the STEAM platform to configure the wireless controller to game play settings with the generous help of both of my teammates as shown in the video clip titled “Controller_to_Game_Integration.MOV” within our Google Drive. One of my two deliverables for this week involved me having to integrate the Node JS server with the forceful jump event’s game data. This helps confirm whether the Node JS server can relay our game data successfully to our simple motor circuit. This was successfully achieved as result of the effective testing of the Node JS server I conducted last week which allowed me to easily pinpoint the bugs within my integrated code and fix them.

My second deliverable for this week consisted of testing the Node JS server on the Arduino WIFI Rev while it is still connected to my PC, before proceeding on to establishing a wireless connection. This was efficaciously achieved on Friday, 24th March with the assistance of my teammate Amelia.

I also changed the game action keys on the frontend of the game to match that of our controller configurations as an added customization to The Last Spartan. We utilized the mappings expressed within our design report whereby the W-A-S-D keys correspond to the left-most joystick; the “k” key corresponds to the left trigger/ left bumper; “j” key right trigger/ right bumper; “p” key corresponds to the “Options” buttons; “SPACE” key corresponds to button “A” and the “ENTER” key corresponds to button “B”.

I eventually played the game wirelessly to test all the integrated components together while also measuring latency of our system by taking a video of the motor activations that occur in response to forceful jump events. According to the video I believe that my software system has minimal latency as shown in the video clip titled “Game_Data_to_Server_Integration.MOV” within our Google Drive.

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

My progress is somewhat back on track since I have managed to successfully integrate the Node JS server and the JavaScript listeners that track the forceful jump game action. I still have to integrate my software components with the hardware components that my teammates have built in order to have a working prototype by the time we have our interim demo. I will still be focusing on how to use Puppeteer to acquire data from all the remaining game actions for this upcoming week.

What deliverables do you hope to complete in the next week?

This week I plan to incorporate a web scraper library known as Puppeteer in my existing software to aid in tracking the game actions of the remaining three events, namely small hit, large hit and low health. Puppeteer will help me analyze different enemy actions in order to accurately transfer data relevant to the game action taking place. For instance, we would not want a low health event to be flagged every time the life bar decreases, instead we would like this event to be activated when the bar decreases to 25% of its original length.

Moreover, I plan to test my software on the Arduino WIFI Rev after establishing a wireless connection.