This week, I finalized the hardware. In the picture below, the frame and the Arduino can be seen along with the laptop to be used for the demo. At the moment, we have simply taped the frame onto the screen.

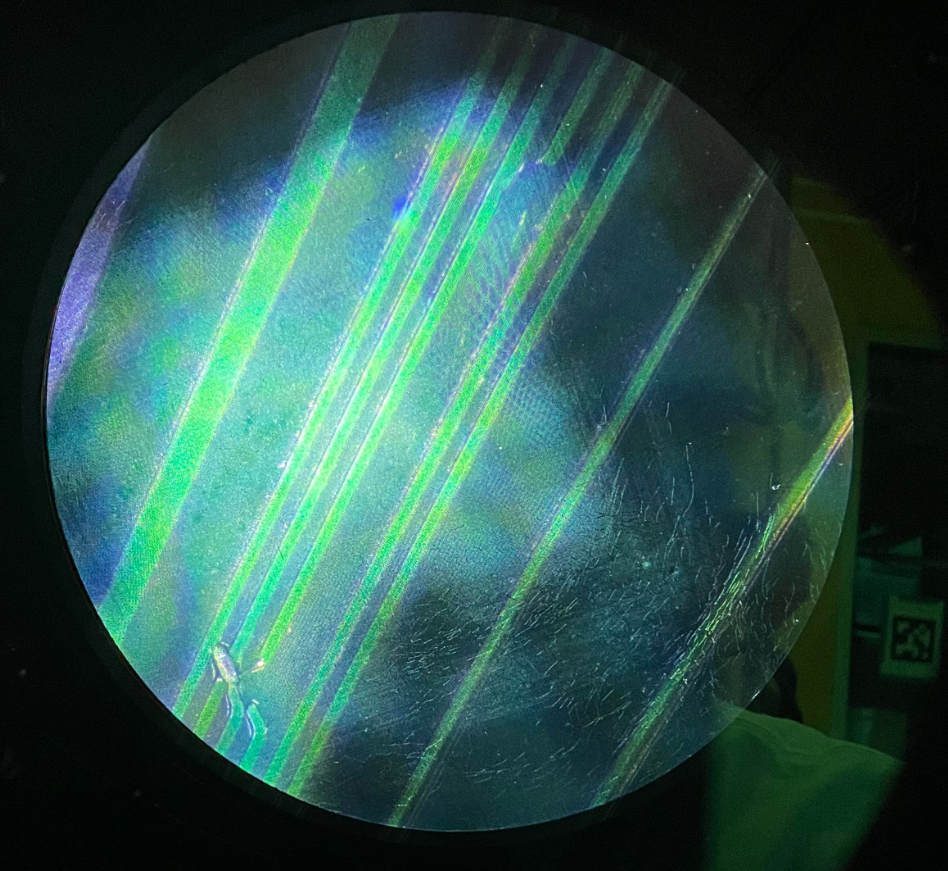

More specifically, I had to work on the long edges this week to complete the frame, as the short edges were tested last week. Unfortunately, after we had already soldered all of our components to the long LED frame, I discovered during testing that JLCPCB had misprinted our board (seen under the microscope below. Fortunately, although there appears to be overlap in the image, there was no short between the wires, so all that was needed was a grueling process of hacking jumper wires between the disconnected nodes. In total, 3 traces needed repair.

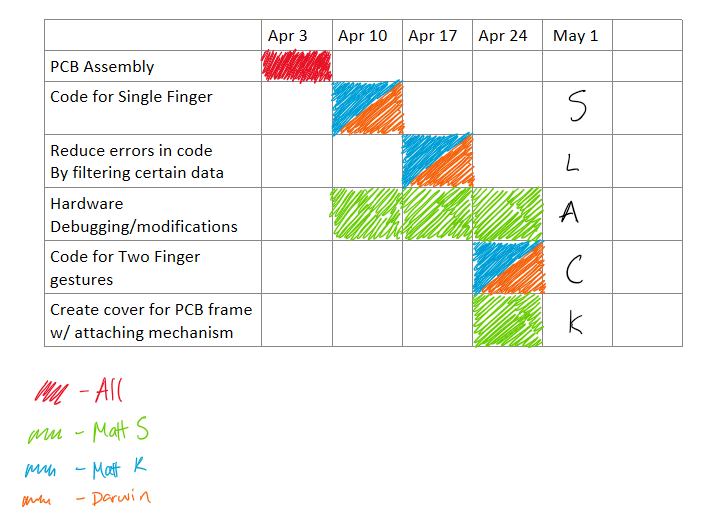

I am now officially ahead of schedule, as all of the hardware debugging has been completed. I can now dedicate my focus to helping on the software end. I will mainly work on optimization going forward, as there are several pieces of the code that I know could be accelerated using bit arithmetic. I also may figure out a better way of securing the frame to the laptop than with just tape.