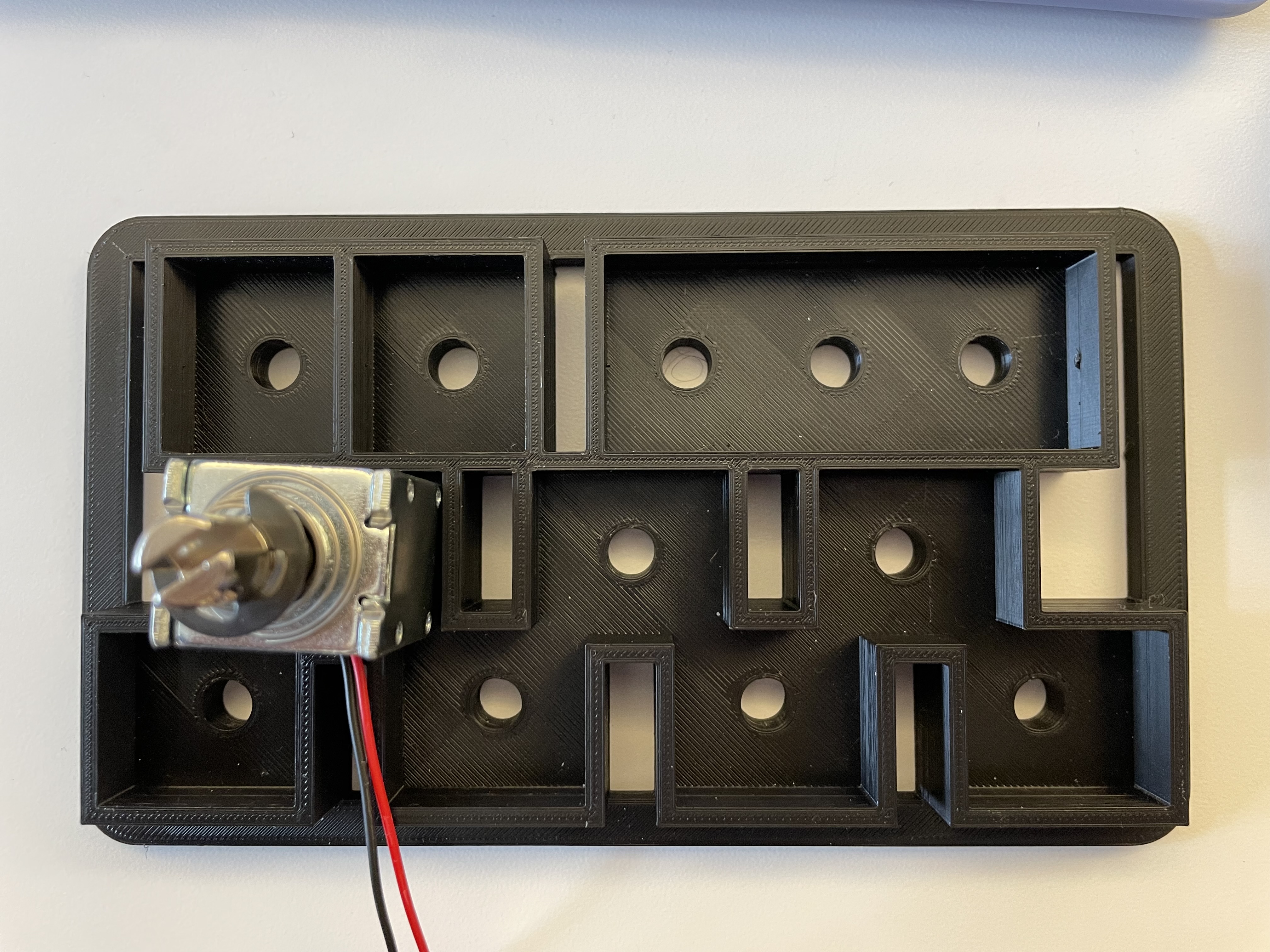

This past week I did not accomplish as much as I had hoped due to having multiple exams and assignments due. The main thing I completed was adjusting the 3D-printed model to fit snuggly around the solenoid rather than loosely fitting and getting stuck after retracting. Using this new design/information, I can replicate it across the entire chassis design so that the solenoids do not move as much and get stuck. Aside from this adjustment, I did not accomplish as much as I had hoped to.

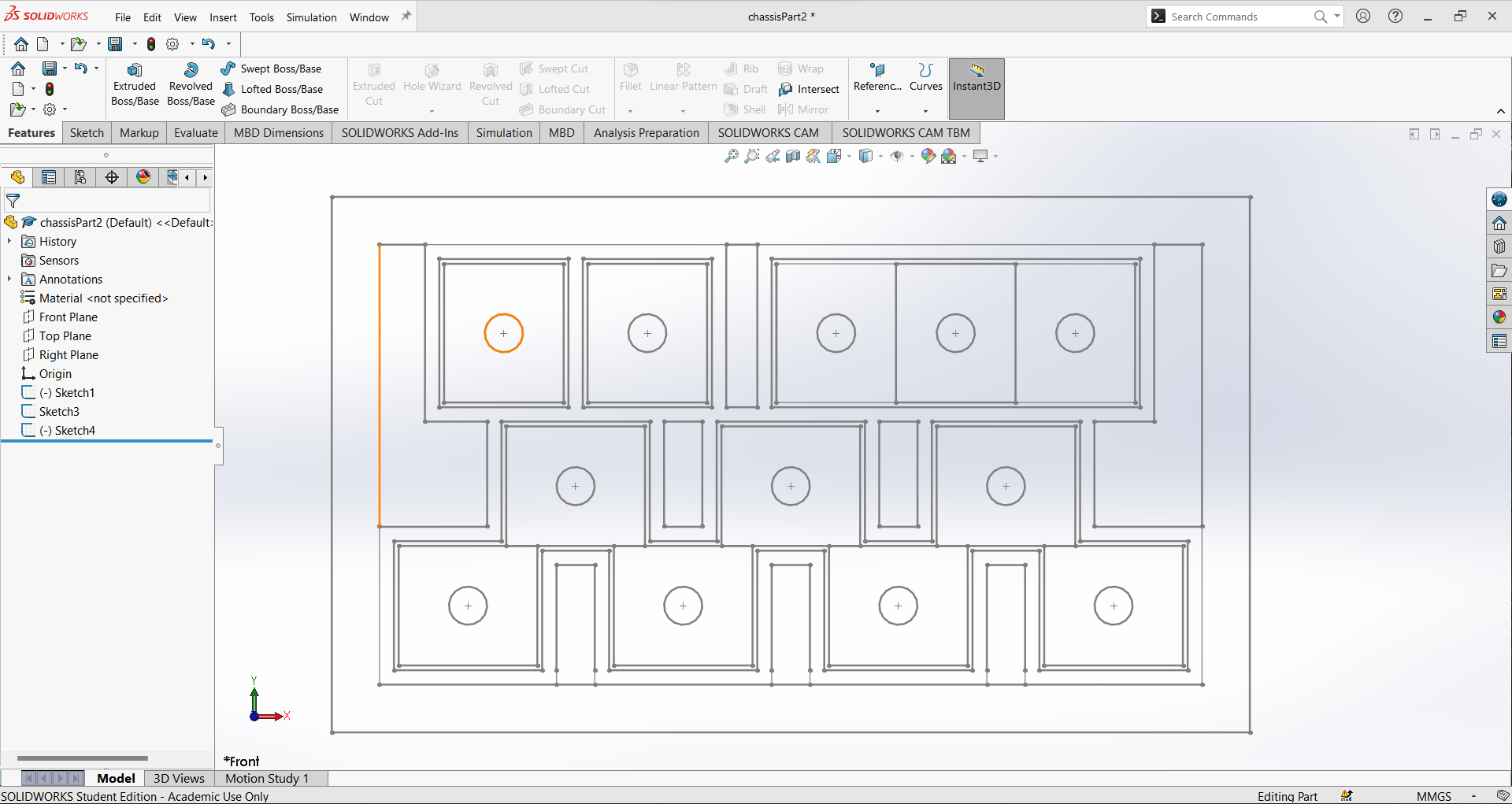

In the coming week, I hope to finish much more. Now that classes have finished and I have almost all of my other assignments completed, I hope to be able to dedicate much more time to completing the chassis. Other than replicating the new dimensions mentioned above, I have to add some support to hold the chassis up while it is suspended over the piano keys. Additionally, we went out and bought metal rods so that the chassis could rest on top of them and suspend over the keys. With these two additions, the chassis should be successful in hovering over the keys, and the only thing we need to ensure after that is that it presses the keys when needed. If that is not successful, I plan on making cylinders to extend the solenoids’ reach so they can press the keys. Once all of this is integrated, it should successfully press down on the keys!

I hope to have a new Solidworks model as well as a freshly printed chassis model by Wednesday. If both of these are successful, we should be set for demo day. If not, we will continue iterating up until demo day.