This past week, we presented our Final Presentation. During the presentation, we explained the technical challenges we faced and the design tradeoffs we made throughout the design process.

Currently, the main risk we face is being able to 3D print the complete casing within the time left before demo. To mitigate this risk, we will be printing the finished casing in smaller sub-parts and assembling them together. This allows for each individual part to take less time to print, meaning we can more easily adjust the design and reprint the part if there are issues with the physical dimensions.

We carried out an entire system functional test from application to solenoids. This worked out fine. We also have conducted tests to verify each subsystem’s functionality. Our results from this testing in previous weeks have helped us to avoid making any new design changes at this stage of the project. The majority of experimental findings was done in determining latency timings as well as OMR parsing accuracy.

These were the methods we used to test specific requirements:

-

- OMR Accuracy → Reconvert back to pdf and compare visually

- Tempo accuracy → Measure tempo with a metronome

- Computer/RPi Latency → Function records system time when start/stop signals are sent and received

- Power Consumption → Measure DC power supply output voltage and current to calculate power

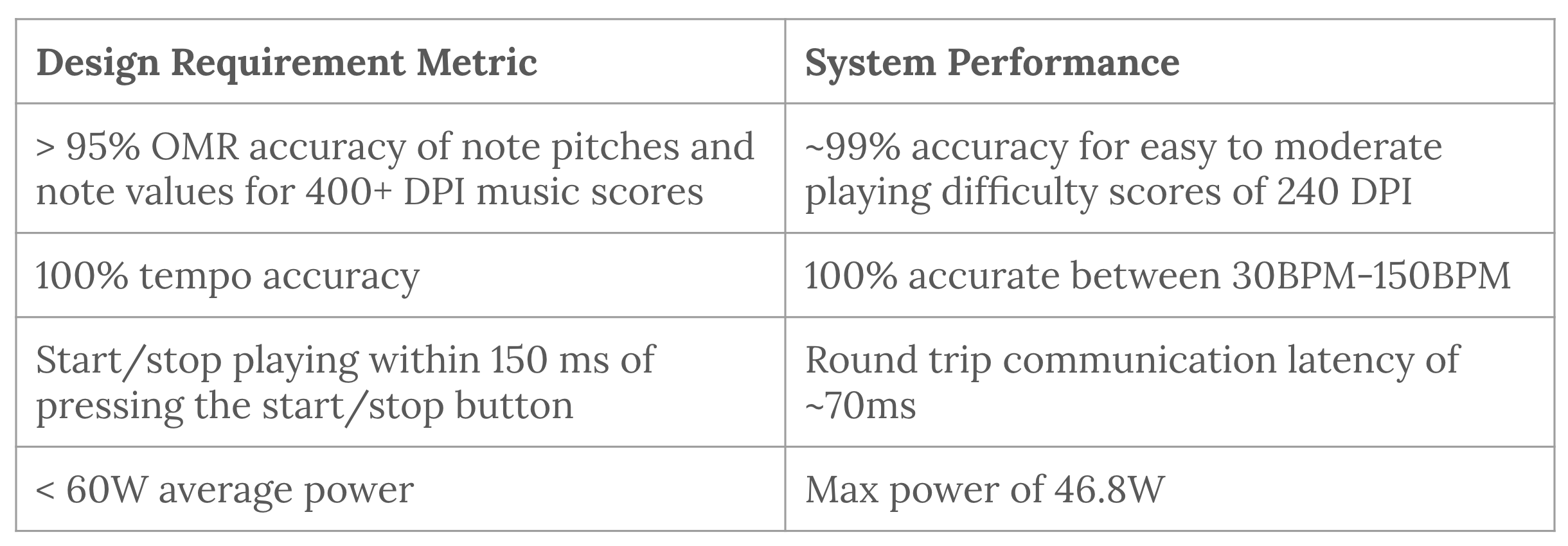

The table below summarizes the results we found through our testing

These metrics show that we pass on all four requirements.