What did you personally accomplish this week on the project? Give files or photos that demonstrate your progress. Prove to the reader that you put sufficient effort into the project over the course of the week (12+ hours).

I was able to start assembling the PCBs and start testing them. The PCBs and parts arrived Wednesday, which wasn’t in time to use them for the interim demo, but I was able to start testing them afterwards. On Wednesday, I put together one motor system and verified that it worked as intended. With the PCB assembled, Amelia was then able to size and laser cut the final motor system holders out of the final rubber material. After putting together the rest of the 5 PCBs I had on hand, I mounted one PCB to the motor system. Along with the laser cut fabric pockets, we now have our final vest assembly components.

To move forward with the final vest assembly, I am also in charge of reversing the zipper on the best as we turned the vest inside out for our project. I was able to test removing and sewing the vest on the demo vest.

Figure 1: Soldered PCBs

Figure 2: The final motor system assembly

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

I would like to be further ahead on testing in order to receive more user feedback, but I am currently on schedule to finish my project.

What deliverables do you hope to complete in the next week?

I hope that the rest of the PCBs will come in late next week. For early in the week, I will work on vest assembly and hope to reverse the zipper on the final vest, install the fabric pockets for the motor systems, and begin the final wiring if the rainbow ribbon cable comes in time.

Now that you are entering into the verification and validation phase of your project, provide a comprehensive update on what tests you have you run or are planning to run. In particular, how will you analyze the anticipated measured results to verify your contribution to the project meets the engineering design requirements or the use case requirements?

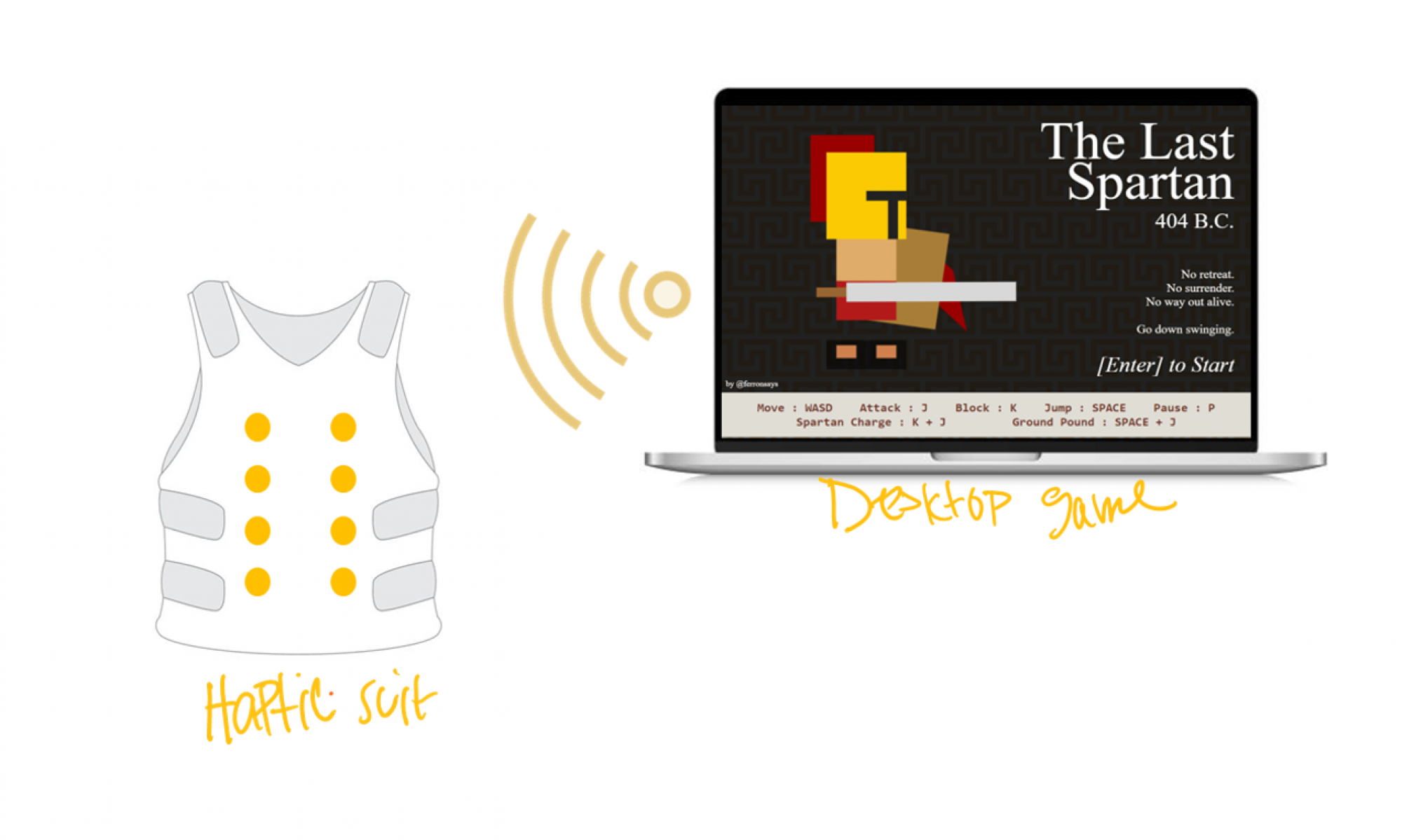

For validation, I plan to check the technical side of the motors as well as collect some user data for the sensations of the motors. For the technical checks, I need to determine how quickly different responses will take to run and how to make them differentiable. This ties into the use case requirements of allowing for 10+ responses per minute and providing unique feedback patterns. Currently, I need to do a bit more work before I collect user input. I will position the motor system pockets and then ask for user feedback on the motor sensations. With only five PCBs currently, I will most likely have to rotate the motors test test the sensations for different parts of the torso.