What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

We were very careful and sought a lot of feedback from our TA and professor when designing our PCB for the motor systems. However, there could still be an unforeseen problem when we start to test them next week. Without the PCB, our vibrational feedback will not be as effective and may jeopardize the sensations we want our users to feel.

We also noticed that the RGB lights draw a significant amount of current, so much so that the 6V battery supply to the microcontroller was not enough to keep all the lights running at a high brightness setting. If we add a second power supply, the lights are able to run at a high brightness and there is some heat emission. The heat emission is not noticeable or uncomfortable when you put on the vest, only if you place your hand directly over the lights. We don’t anticipate the heat of the lights being a risk factor, but we did want to acknowledge it.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

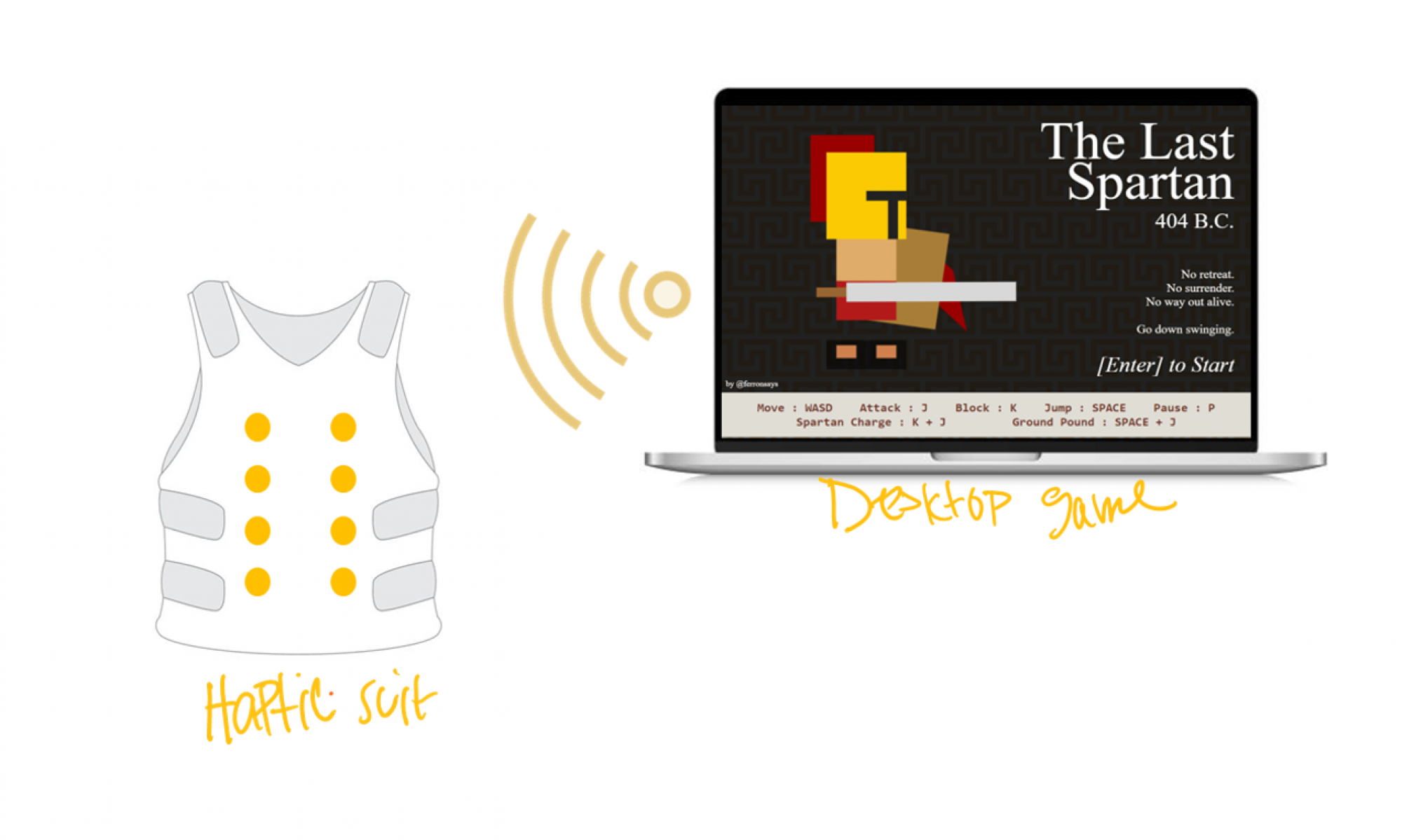

This week, we had our ethics discussion. The other groups brought up several points we did not originally consider in our design. One of the biggest concerns brought forward was the idea that someone could remotely control the vest using the wireless controller. When we decided to move to a fully remote system, we had not considered how incorporating a remote controller might be dangerous to the person inside the vest. To avoid this, we plan on implementing an emergency stop switch into the vest which can turn everything off immediately. This will allow people who feel uncomfortable to stop the vest. This emergency stop will be a physical system between the power and the devices that are running, preventing any delays sending a signal to the Arduino may cause.

Other concerns included how hot the vest would get and how accessible our product would be for people who have limited arm mobility. For the heat, we were able to test it out, as stated in our risk factors. We interpreted the latter as a concern of putting on the physical vest. To make putting on the vest a smoother experience, we decided to put optional Velcro strips that run horizontally across the middle of the vest (under the zipper) so that a user is able to secure these strips instead of the zipper, which may be hard to use.

A design change we made this week was the inclusion of Velcro strips to the inside lining of the vest in order to vertically secure the light and motors systems. The user will not see these strips, but it does allow us as the designers to easily access the motors/lights, provides minimal movement, and a seamless outside look that avoids any additional sewing.

Provide an updated schedule if changes have occurred.

We are on schedule. Next week, we will focus on integration and cleaning up our individual contributions.

What we got working. Video of putting on the vest can be found here.