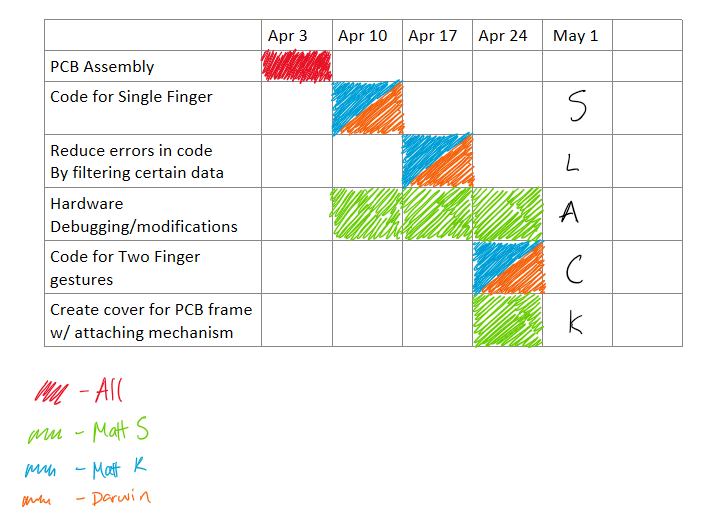

This week, I made some very significant progress on the hardware side. Since we finally got the decoders, we were finally able to start testing our design as it will be in its final form. To begin, I wrote an Arduino script that could sweep through the entire left/right diode arrays. While testing, I came across a single bit error, where it appeared as though a photodiode was always receiving light, even when blocked. That is, instead of the anode dropping from 5V to 0V, it would only drop to 3.4V for some reason, which was not enough to force the mux input low. I tried resoldering and replacing its 210k resistor to no avail. Then, I tried replacing the photodiode, after which nothing changed. So, I decided to replace the multiplexer, as that was my last guess as to what could be wrong. This proved to be the issue, as the new mux worked seamlessly.

Another thing I did was start soldering the long (top/bottom) edges of the frame with Darwin. This process is almost complete; all that is left to be done is to solder the photodiodes into the top. As for next week, I will modify my Arduino script to test the top and bottom. Using this script, I will do some hardware debugging. If all the components and circuits work, there may be some time to start integrating the hardware with the screen control, as Matt K has been working on the Python code to transfer the data. In sum, I am at least on schedule. Depending on the functionality of the components on the top/bottom PCBs, I might be ahead of schedule by the end of the coming week.