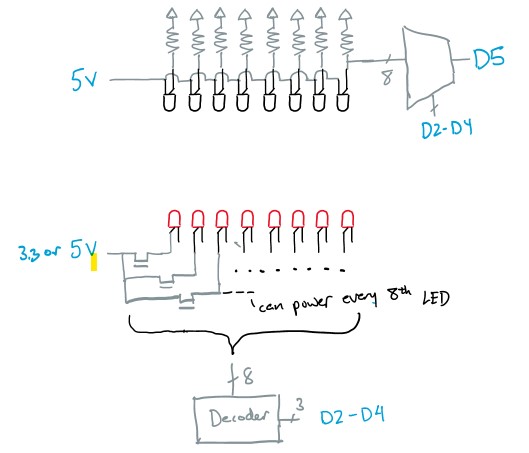

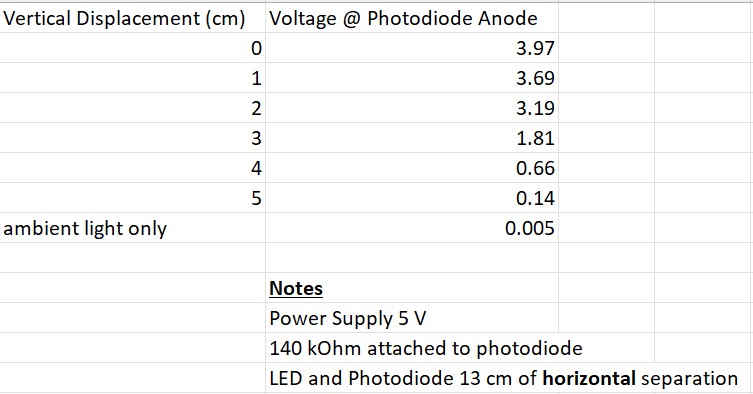

Overall, we feel that we made significant progress on our project this week. The most important update is that we switched from an analog approach for determining finger position to a digital one. This change affords us several advantages; for one, it eliminates the need for a preliminary simulation, giving us at least an extra week of slack. Additionally, it removes a lot of the complexity of an analog approach, as digital detection will be far more immune to noise. The largest drawback of this approach is that it is more brute-force than the analog, and we will need far more diodes, which could provide some challenges as to how we package the circuit into a limited form factor. However, we think the pros significantly outweigh the cons, as the digital implementation is less risky in the long run. Our block diagram from the initial proposal remains largely unchanged, since our initial idea was also a digital approach.

We have identified two risks that could significantly affect the outcome of the project. The first is that we have limited space on the bottom edge of the laptop to place the hardware. Before switching to the digital approach, this was not a concern since the hardware would have only been on two edges, but it now needs to be on four edges since we are creating a 2D grid. For the laptop we plan to design the product for, there is currently an inch of vertical space below the screen for the hardware to be placed, so we think it is possible that this is sufficient. However, since it is not a guarantee, our current plan would be to build outwards towards the keys if we need more space. With the shift of our schedule, we should have more time to focus on the design of the frame, so this hopefully help mitigate the risk. A second risk we have identified is that the cost of the PCBs may put us over our budget. With our new approach, we have decided that PCBs are probably necessary in order to hold the hardware components in place. We currently do not have a specific estimate of how much this will cost, but we our planning to figure this out in the next week. As a worst case scenario, we have decided that we could have a 2D touch grid on the side of the laptop if we become affected by these risks.

Updated Schedule: