This week was the last week we could actually put in work before the video, so it was a very crucial week for us since we had to ensure we had at least our MVP working for the video.

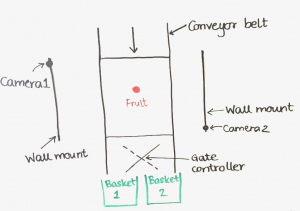

The team worked on figuring out how we can attach the servo to the diverter we had printed. We, then, fixed our image segmentation masks to ensure we were detecting the rotten and good parts of the banana correctly. Once we figured that out, we set up our final product and ran several tests to see if we were meeting the metric requirements we had set out to meet. We seem to be meeting the requirements, at least for the MVP, for now. We’re working on image segmentation for carrots to be able to include that into our product, and we’re also working on developing the AlexNet rottenness classifier, so we can see how it’s performing in order to be able to compare it to our current classifier and gain insights. We’re now working on the final video and poster.

Below is a picture of our final product setup. We would like to thank Prof. Savvides and our TA, Uzair, for all of their help and support throughout the semester!