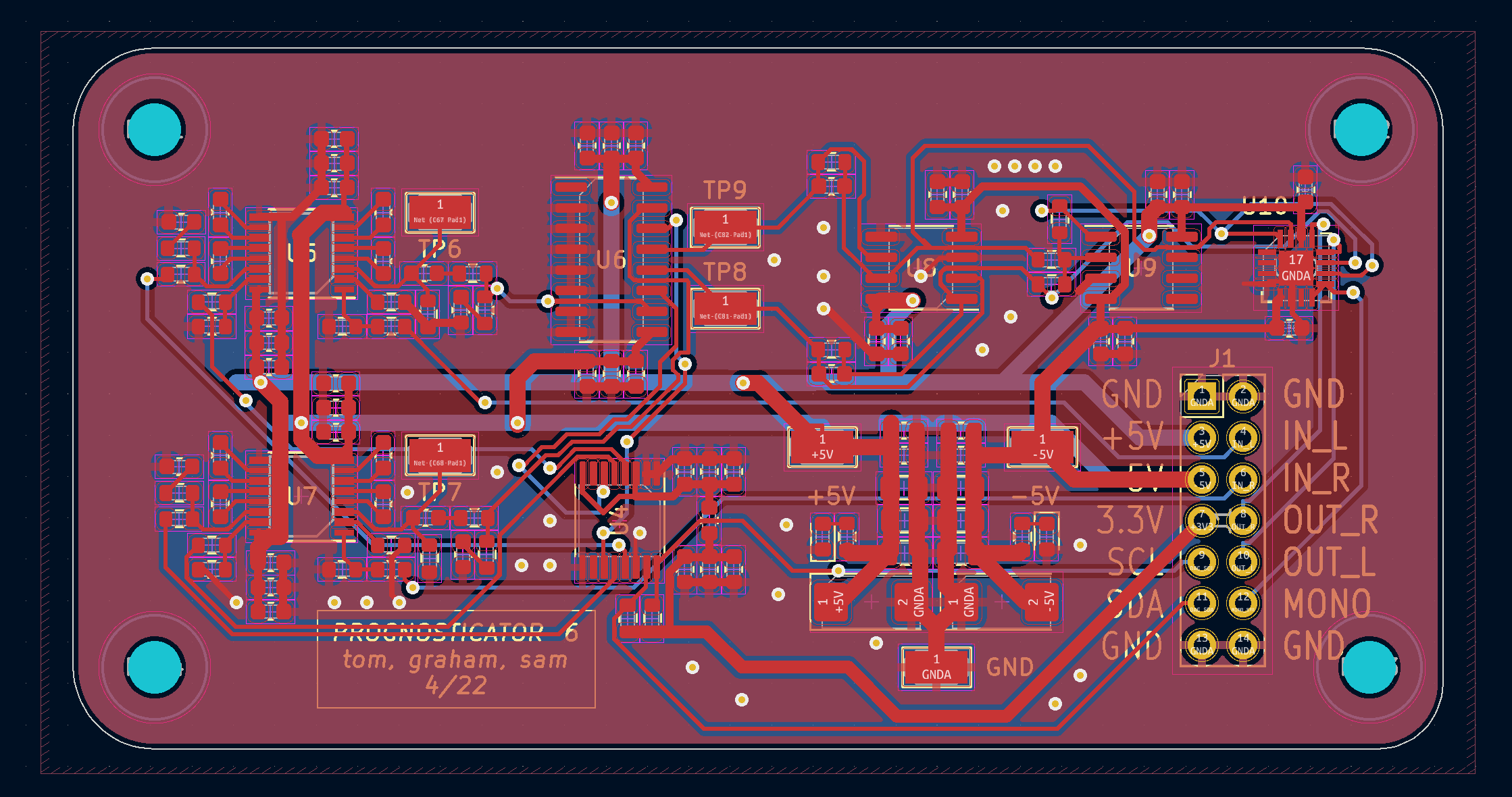

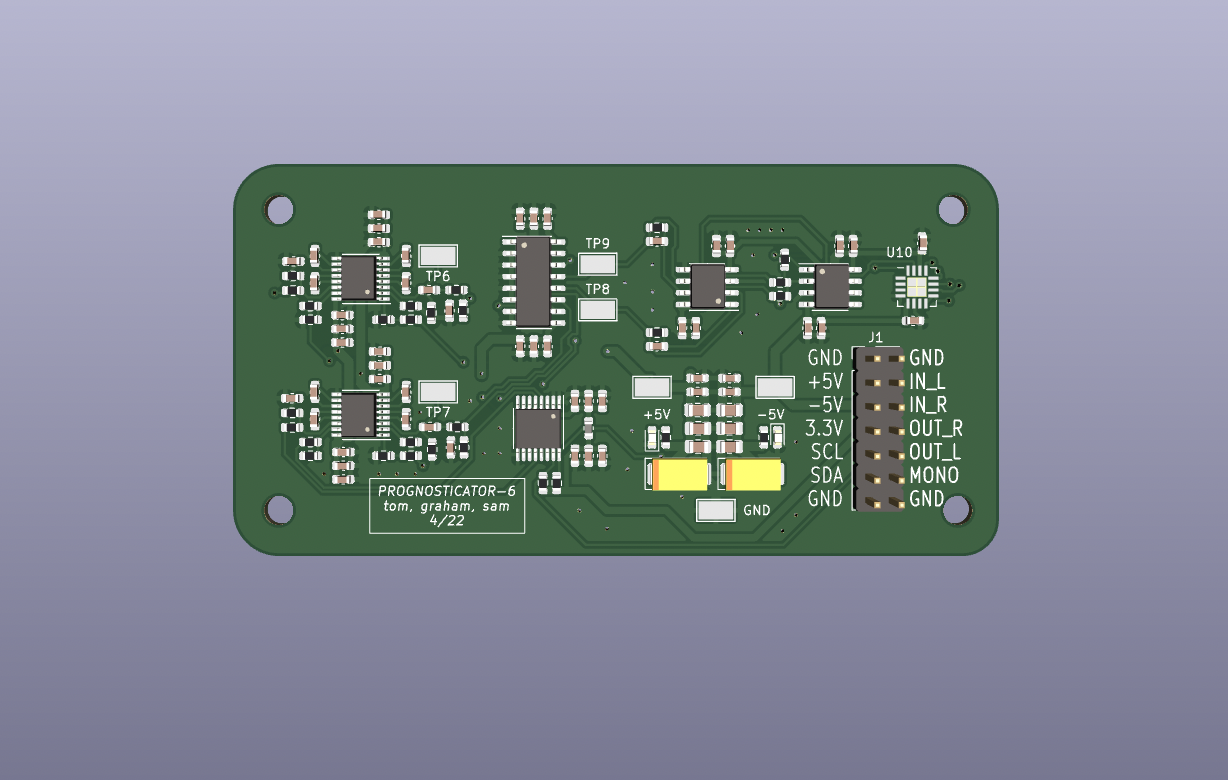

I have completed the PCB layout and ordered the boards from PCBWAY in China. It’s a fairly small 2-layer board with typical design rules and about 100 components which will allow the board house to manufacture it quickly (2 days) and us to solder everything in a few hours.

The chip shortage has caused a number of the components to go out of stock while I was laying out the board causing me to start over. Luckily, we were able to get the whole BOM finalized and ordered for this PCB layout. All parts, including filter ICs, are in-hand. Once the PCB arrives, we can solder all the components (reflow with stencil) and begin bring-up and testing.

Laying out the board took longer than expected and put us a little more than a week behind. To get back on schedule, we need to have the board in-hand by the end of this coming week and verify that all the component footprints are correct. The main deliverable for next week should be a soldered PCB that is ready for testing and integration into the enclosure.