The past 2 weeks, I worked with the team to fine-tune the overall process of the robot and help reduce errors as much as possible. Most of the errors we ran into were related to drifting, slight battery charge change effects, connection issues, or communication issues. Some of them are reliably debuggable (i.e. battery charge or connection issues), but some are random and hard to pinpoint. Overall, the robot performs somewhat reliably but we seek to continue to improve on the process as much as possible for the final demo.

Esther Jang’s Status Report for 11/20

This week, I worked with the team to do testing as described in the weekly status report. We are currently incrementally programming the various steps of our robot’s navigation process which has required a lot of on-hands testing and discussions for problem solving. With Thanksgiving break approaching, we are hoping to be done with our target implementation soon, which may be possible with our current progress.

Esther Jang’s Status Report 11/13

Since my subsystems were completed and have been consistently performing as normal since last week, I did not make any changes to the linear slides nor claw subsystems. All of my work for the week was done with the rest of the team to help implement navigation/integration as described in the team’s weekly status report.

Esther Jang’s Status Report for 11/6

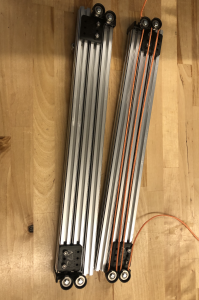

This week, I worked on mounting and motorizing the linear slides on the robot. Both slides were mounted mirroring one another on the chassis. The pulleys were strung with a string that was attached to the motor that would pull the slides. I found that the motor alone was insufficient for lowering the slides, so I added some tension to pull the slides down when unwinding the string by attaching surgical tube between adjacent slides.

Overall, the slides were able to successfully extend and detract with a bar mounted between them as shown in the following clip:

There are some slight issues with detracting fully which I think is related to minor tension issues. The slides were able to individually detract otherwise.

At one point in the week, one set of slides were completely stuck and required significant disassembly to resolve. In order to fix and further help avoid this issue, lubricant grease was applied to the slides.

Finally, I also tested the claws this week and found one to have significantly better grip range and torque than the other. Using the servo code written a few weeks ago, I was able to get the claw to grab a small, light box. The claw was also mounted onto the end of the slides.

Esther Jang’s Status Report for 10/30

Our parts finally arrived this week, so I spent the week building. Unfortunately, I was unable to work in-person for Wednesday and Thursday due to a potential COVID exposure. Hence, most of my work took place on Monday, Friday and Saturday.

I was able to complete building the mechanical aspect of the linear slide system (not including mounting). We did not integrate yet because we ran out of nuts for building but will receive more by tomorrow. The slides seem to extend fairly well although they were getting slightly stuck at times. I think this could easily be fixed with a bit of lubricant. The length of a single slide is 1/3 meter (full meter extrusion cut into thirds), and each set of slides is a mirror of the other.

I also investigated the motor shields with Ludi and was able to control a motor so that it spins at a specified frequency of a specified amount of time, holds, and spins in the opposite direction the same way. This should be approximately the operation we need for the linear slides.

Finally, I attempted to get the claw working with the Arduino code written last week but found that the servo required a voltage of around 6-8V to operate. We will likely need to get a buck convertor to use the claw’s servo.

Esther Jang’s Status Report for 10/23

This week, we placed an order for our parts early this week but unfortunately did not receive any of them yet. As a result, I spent time preemptively investigating software aspects of our hardware.

For the claw, I tested controlling a servo through the PWM output on an Arduino board. Although we intend to put them on the Jetson board directly, I tested with the Arduino since I didn’t have access to the Jetson this week. I found that it was very straightforward to run a servo on the Arduino, so we should strongly consider running it there instead of the Jetson if possible.

I also looked into the encoders on the motors and found that they were incremental encoders that have a channel A and channel B pin that needs to be connected to digital pins. In order to keep count of the encoder, we need to compare the signal of the channels with each other as they are out of phase. This also means that we need 5 pins for each motor that uses the encoder – 3 for the motor and 2 for the encoder. As a result, we will likely need to use 3 Arduinos as opposed to our current plan of 2. Overall, using our encoders should not be too difficult as long as we can properly read the pins.

Esther Jang’s Status Report for 10/9

Last Sunday, I worked with the team to finish up the design presentation and spent a few hours for presenting it. I ended up presenting on Monday and learned a lot from other groups’ presentations.

Throughout the week, I worked closely with the team to reevaluate and discuss solution ideas. In particular, I helped give feedback to and researched the drivetrain design with Ludi in terms of evaluating motor drivers and compiling an initial bill of materials. After realizing that the motor driver we were initially considering had insufficient current output for our motors, the BTS7960 ended up being the best motor driver solution we could find. We also met up today to thoroughly discuss the hardware solutions we are using and ensured that they synthesized together and had appropriate power systems.

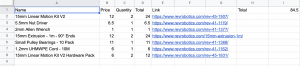

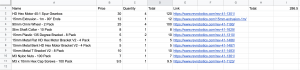

Bill of materials for linear slides + drivetrain:

We also realized that our bill of materials was more costly than anticipated, so we ended up pivoting our linear slides to being powered by Nema 17 stepper motors instead (from the inventory).

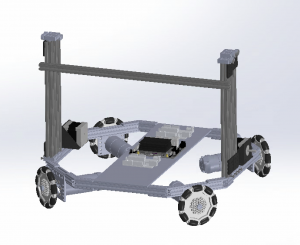

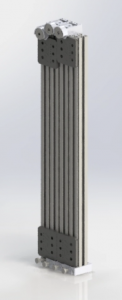

Furthermore, I integrated my linear slide system CAD to Ludi’s completed drivetrain CAD (pictured below).

Finally, I have been wrapping up my research for the servo-controlled claw and plan to spend tomorrow CADing it. Most off-the-shelf parts seem to be unfortunately small and I have seen promising claws made from laser cut parts. In particular, I found the following post to be very useful: https://imgur.com/gallery/LpyW3 and the following book chapter: https://link.springer.com/chapter/10.1007/978-1-4302-6838-3_11. The design of such servo claw systems seems to be fairly standardized (claw arms paired by gears and composed of 2 links).

Esther Jang’s Status Report for 10/2

This week, I spent most of my time doing CAD on Solidworks or researching design options.

I first made considerations for our linear actuation system. Given the height requirement of our robot, I thought it would be best to use a linear motion kit and decided to use the following pulley system described here: https://docs.revrobotics.com/15mm/linear-motion-kit. The primary motivation behind this selection was that it was built to sustain a multi-level cascading height that could reach our height requirement of 3 ft. Furthermore, it is very mounting-friendly for other parts (such as our claw or drivetrain) and price-accessible. This is better than other alternatives that are often significantly more expensive or cannot meet our height requirement (most common problem). I assembled the CAD for this part by using the standard part library from the vendor. The process was time-consuming as I had to relearn how to assemble with CAD, but I believe that it was valuable experience to help me with CADing the remainder of my part of the project.

Linear slide system CAD render (based on https://docs.revrobotics.com/15mm/linear-motion-kit/three-stage-cascading-lift)

I also invested several hours into checking the viability of using a vacuum suction gripper, following feedback from a recent meeting to consider it. Using a vacuum suction gripper was a good idea because of the benefit of reducing room for error and for emulating current industry solutions of our idea (i.e. https://www.youtube.com/watch?v=zeKfvUVbO3g&t=4s&ab_channel=IAMRobotics). The main issues I was facing in my research were the following:

- Limited amount of information about the performance of diy suction gripper kits: Most vendors make claims about the performance (i.e. how much load the system can carry), so this was the only basis we could make a decision off of. I was unable to find much solid, unbiased research to support these numbers quantitatively aside from anecdotal videos of performance.

- Limited availability of diy suction gripper kits: Almost all diys I could find were using some version of a standardized suction gripper kit that seems to only be sold from Chinese vendors and with an estimated shipping time of 1 month out in early Nov. There was also a single vendor on Robotshop that sold a potentially promising suction gripper system that uses a syringe+servo system instead of an air pump. The description claimed to be able to have a load of 3oz (0.21lbs) which could potentially be too poor of a performance.

Overall, the vacuum suction idea ended up being too high risk given its limited availability, so we decided to safely abandon the idea in favor for a claw.

Currently, I plan to use a claw system that is similar to off-the-shelf standard grippers (such as https://www.robotshop.com/en/actobotics-perpendicular-standard-gripper-kit-b.html) that is powered by a servo. The reasonably priced off-the-shelf parts do not seem to meet our requirements for objects to grab (small size maximum grip size of 4in and unknown (but likely very light) weights. My current research seems to indicate that CADing and laser cutting the claw is likely the correct direction, so I will continue to look in this direction (i.e. https://imgur.com/gallery/LpyW3).

I believe I am on track as the design research I did was thorough in making sure the chosen designs meet our requirements and are reasonably priced. I will be finalizing the claw idea and expanding upon the electronic hardware evaluation done last week by early tomorrow (in time for the design presentation).

Esther Jang’s Status Report for 9/25

During class this week, I watched other groups’ project proposals and found them to be really interesting. I spent some time on Sunday to help finish up our presentation with the group.

One point that was brought up during the discussion after our presentation was why we were using a claw as our end effector rather than a vacuum gripper. I had previously given the vacuum-powered gripper some consideration but wanted to re-evaluate that choice just in case. In my research, I found that the most reasonable methods to do this given our use case was either using a squishy universal gripper or a suction gripper. However, the squishy universal gripper is better suited when pressing against a smaller object, which does not match our use case. The universal gripper typically molds around the object and holds the mold by vacuuming out the remaining air. The objects we are picking up will not have much normal force opposing the force we apply (since they are freestanding in a shelf) and will not be small, so the universal gripper will not work. The suction gripper will also require a very strong and expensive vacuum pump that is not practical for us to purchase. Typical off-the-shelf vacuum systems seem to only be able to carry 0.22 lbs, so it will not perform well enough.

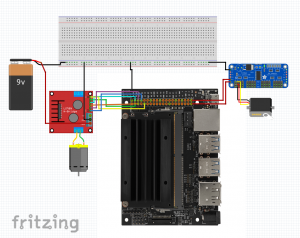

After the above research, I decided to proceed with the servo-powered claw end effector idea. I have yet to solidify the linear actuation method but believe I will likely be using a DC motor-powered linear slide system. With this in mind, I wanted to sketch out the electronics required for my end effector and linear actuation systems. I chose a standard PWM servo and I2C servo driver (specifically PCA9685 in the diagram) for the claw. I chose a H Bridge motor driver and DC motor for the linear actuation system. Both of these choices were inspired by many other Jetson Nano projects I saw using a servo or DC motor, and I wanted to focus on feasibility before refining my choice of hardware.

However, I realized that the battery needs significantly more consideration than I had previously considered. This is because there are many ways to power the Jetson Nano which requires 5V/2A (10W) while the DC motors will require 12V and the servos require 5V (share the same power source as the Jetson Nano). We can either have different power sources for the motors and Jetson Nano or use a buck converter. I have been heavily evaluating the tradeoffs as the Jetson Nano seems to be sensitive about battery sources (i.e. read a lot of articles indicating that the USB power bank source should be avoided). For now, I left the power source for the Jetson Nano out of the diagram but have been focusing a lot of research in this area.

I believe I am currently on track with researching design considerations. After finishing up my research on electronic components, I will move onto CADing the mechanical components.

Esther Jang’s Status Report for 9/18

This past week, I primarily worked on the project proposal submission that was due on Sunday and the presentation slides due tomorrow with the team. I will be working on the linear actuation system (movement along the z-axis) and the claw grabbing system of the robot. The feedback we received during our week’s meeting (as mentioned in the team update) did not change my side of the project too much, but I have been continuing to do research on these parts.

Currently, I am planning on using linear slides with a motorized pulley system for the z-axis actuation. I have some concerns about the stability of this system, especially given that we will have to take snapshots at the extended unstable heights. There are many standardized servo-actuated claw systems to use for the claw that we can purchase online, but I also may consider 3D printing one. Most of my research has been on these 2 components while keeping these considerations in mind.

My progress is on schedule but I think my next step is to start writing CAD and to start seriously considering what the design of the grabbing system will look like.