The beginning of this week was heavily focused on the final presentation. Aidan, Neha and I met up to verify a lot of the metrics, finalize the content that we wanted to include within the presentation, and update the diagrams to more accurately represent the current state of the project. In additional to the overall content of the presentation, I had to focus on the actual presentation, and making sure that I knew what I wanted to say on each slide; this was relatively simple seeing as I am very familiar with nearly all parts of the project, but I could have used to work on overall pacing more.

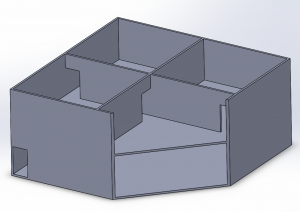

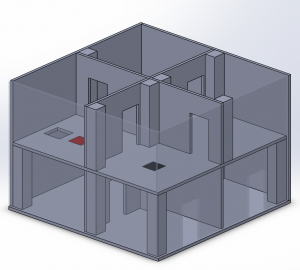

Following the final presentation, I continued to work on the scale model that we will be using for the demonstration. I had a mockup during the last status report, but I decided to add to it and include more detail, such as how we will actually be framing it. I also put more thought into the floorplan; I tried to focus on thinking about which nodes will be good ones to show as detecting fire, and how that will impact the general path routing. I also wanted to ensure that we took advantage of the 2-story nature of the design by adding rooms on the first floor as well. This was a challenge, because the first-floor was hard to see, so after some deliberation, I decided that the best course of action would be to use wood framing for the majority of the model, but then use acrylic on two of the four exterior walls so that it would be easy to see into the model. Here is the final version of the model we will be building.

At the time of writing this, most of the parts have been cut and laid out, and assembly will happen in the next day or two.

One of the other things I have been focusing on is completing the distributed pathfinding. I have been running into some trouble with making sure that each node has the full list of paths necessary to reach the exit. Currently, I am storing the NodeIDs as a linked-list as it is being generated. This then has to be reallocated into an array once a fixed size is known, and broadcasted to all neighbors, so that they can also have access to the exit path. The issue is there is a fixed packet size that is allowed to be sent using ESP-NOW, and when testing with large graphs, this is exceeded. I tried to write a fix that would send multiple packets if the packet size was exceeded, but that had bugs.

I plan on finalizing the the pathfinding tomorrow and doing my best to ensure it has the same results as the existing pathfinding which I have tested thoroughly. To do this, I will include both header files and run both versions of pathfinding and check if they ever differ. I will also be using this to test the differency in latency between the two implementations, as that was one of the key worries we had when switching over to distributed path finding.

I am slightly behind schedule at this point, as I was supposed to have distributed pathfinding done at this point, and only be working on the final documentation, poster, etc. Seeing as this is the last week, though, I will likely just extend the duration of the task, rather than updating the Gantt chart, as there isn’t any more time to shift the remaining tasks backward.

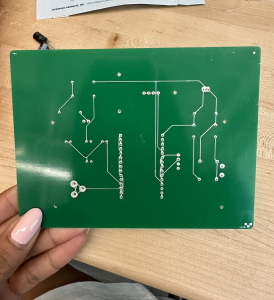

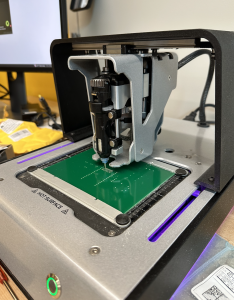

This upcoming week, I want to finalize the model and complete and verify the new pathfinding code – including metrics. I will also be working on the final hardware integration with PCB’s with Aidan and Neha, and then focusing on the remaining logistics files that I mentioned earlier.