Earlier in the week, our team spent a lot of time going through our final presentation slides and adding some more testing metrics and quantitative design choices. We wanted to ensure that we were able to address the design and use case requirements and show how our project had progressed over time and what more we will have to accomplish. The main focus of the week was the PCB fabrication. Early in the week, we caught an issue with the PCBs that we had just sent out for fabrication. As a result, Aidan and I had to quickly redesign, finalize, and send out a new order with the updated design. We also added more trace widths that should have been thicker as well as mounting holes for the batteries. Luckily we were able to ask Quinn to quickly send out another order with our updated design and they are currently supposed to come on May 2. This would mean that we would have to immediately solder and test. However, if they still do not work as intended, we would be cutting it extremely close for our May 8 so we would have to solder our parts onto a larger protoboard.

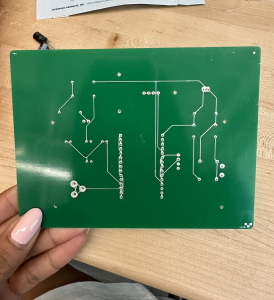

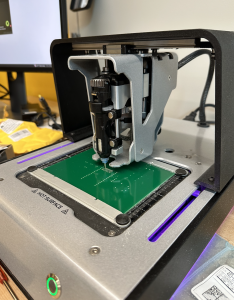

In order to see if our new design was working as intended, Aidan and I reattempted to print our own PCB using the Voltera. This was the first time using the machine without Quinn and it went really smoothly. We used the new 2.5mm drill bit as well which ended up matching the mounting holes on our display, battery packs, and smoke sensors perfectly. The printing process went smoothly as well. However, when we tried to test this by soldering some components to the board, we noticed that when trying to heat the pad with the soldering iron, it was removing the conductive ink. We didn’t expect this to happen especially with the fact that we baked the board in between printing iterations. We also received our original PCBs with the issues that we caught at the beginning of the week and we are trying to see if we can test the parts without the issues that were found or if that is worth spending our time. Soldering components to those boards are a lot more reliable as well. We are hoping to wait for our new boards as they come in but are anticipating the use of a bigger protoboard as well.

Simultaneously towards the end of the week, Jason and I started planning out and building our small scale demo. We spent the first day taking a look at the rendering that Jason created and figuring out the best way to do the rooms. Originally, we went into it thinking that we would just be using plywood but after struggling with ways to connect edges together, we started to make proper frames. We cut out the 2”x2” studs as well as some of the plywood for the interior walls, and we wanted to see if we can go to the Hunt lending booth to buy two 2’x2’ clear acrylic sheets so that we can look into the rooms and be able to see the nodes of interest and how the displays are updated as a result.

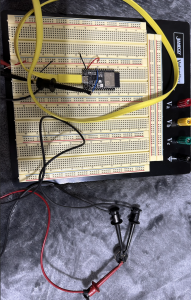

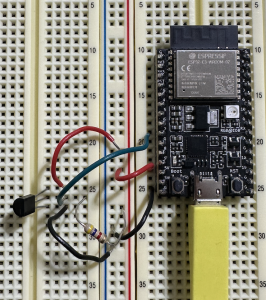

Finally, the smoke sensors came in on Tuesday and I was able to interface with them using the ESP32 and get smoke readings. The nice thing about this sensor is that I can use the potentiometer to calibrate the sensor to the presence of smoke. All I had with me was a lighter at the time, but Jason and Aidan recommended testing using incense or blowing out the candle so I will try that as well as look up smoke readings in smoke detectors as well. The datasheet for the MQ-02 smoke sensor also had a list of thresholds for different gasses so I will refer to those as well and compare to find the threshold which shouldn’t be too hard to add into the existing code once I get that value.

In the upcoming week, we have a lot to get done. Our PCBs will be our main priority when the new designs come in. We also will have to start working on a poster by May 2 so it can be printed by May 4. We will also want to complete our small scale demo as well as work on our final report which is due by the end of the week. While this is our home stretch, we will be having a busy week. We are a bit behind schedule in terms of the PCBs as we had to order new ones, but our schedule highlights the small scale demo, poster creation, youtube video, and final report as tasks for the week which is what our current plan is.