Skip to content

- Week recap

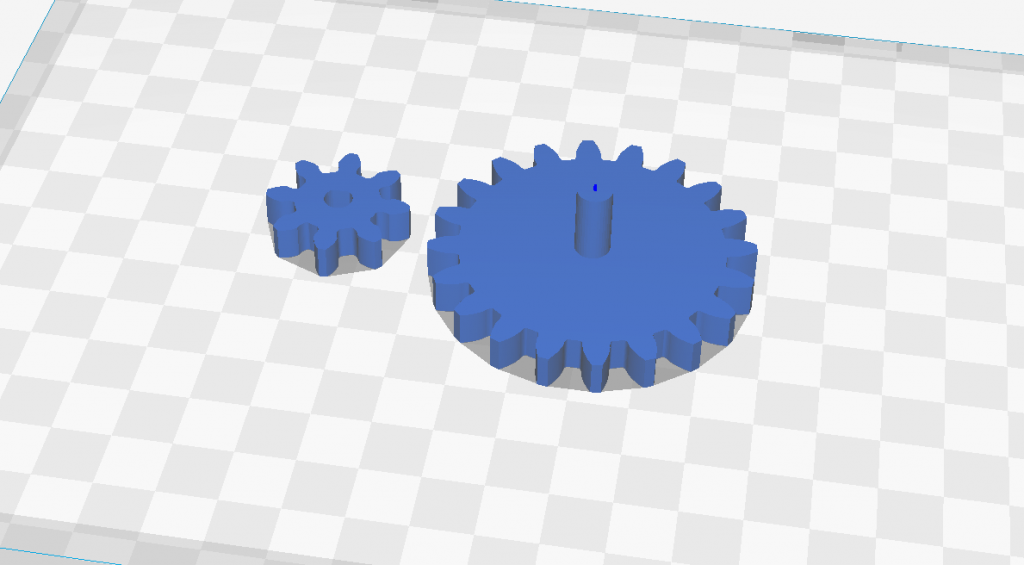

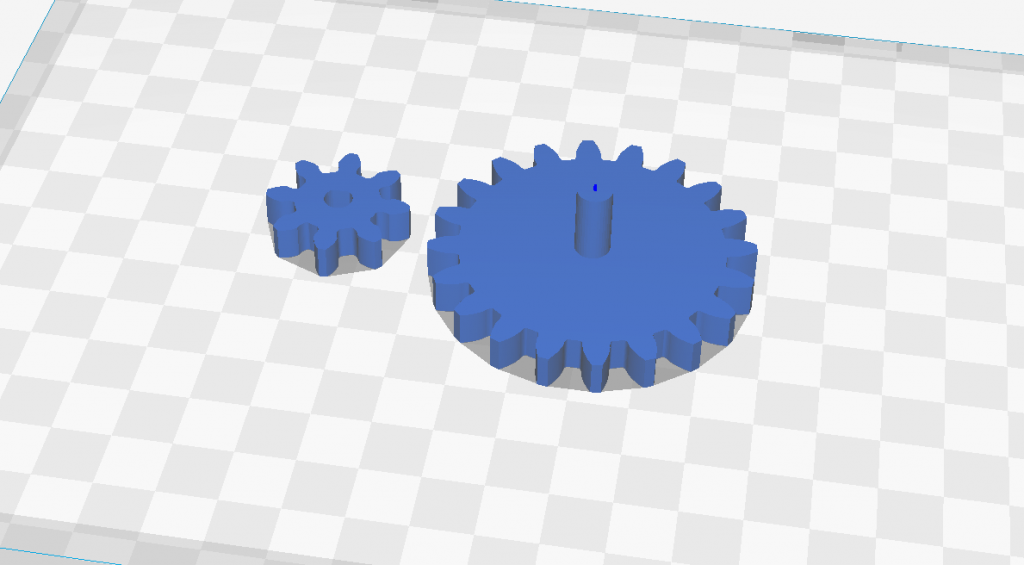

- CAD models for the lift system

- 3D print gears to get our desired torque output from the steppers (each stepper needs to lift 5lbs)

- Initial version of complete, and will be submitted for fabrication on Monday (see image below)

- Plan is to mount these between 1/4″ plywood panels that will make up the arms of our lift system

- Decided on using cams fixed to large gear to lift bins for easy positioning

- Roomba driving

- Was having trouble getting it to enter serial communication mode

- Potential default baud rate issue (115200 stated in documentation)

- Using special boot procedure for reliable 19200 baud comms

- Tethered driving with computer: Drive Code v0

- Schedule

- Slightly behind on CAD for docking system

- Good trajectory this past week, which will be carried forward

- Validate prototype gears and move to full version with cams (rapid progress here)

- Getting more used to Solidworks again

- George assisting with stepper motor control

- Any redesign work can happen over spring break and use slack time for further testing

- Deliverables next week

- Working prototype of the pickup arms, with mount points for gears

- Gear system validation

- If gear testing is successful, make/print the next iteration with cams, otherwise make gearing changes to reach target lift capacity

- May write code with a simpler interface for roomba driving, with more customization on motor speeds (dependent on other group member needs)