Currently the largest risk is still the wireless charging not working correctly. We received the wireless charging kit this week, but since everyone was busy with their own weekly tasks, the wireless charging was not tested beyond basic verification that it worked. Additionally, we are worried about the functionality of the wireless charging through the 3D printed housing. We can mitigate the risk of the wireless charging not delivering enough power somewhat by lowering the idle power consumption of the key device, thus allowing the battery to trickle charge with an extremely low current input. As for the housing, it would be possible to make the bottom wall of the housing extra thin to allow for minimal interference with the wireless charging coils. Another risk is that the configurator software may not be able to precisely identify which of the keys is being programmed at any given time. We plan to mitigate this using numbered keycaps on top of each key, such that it would be possible to select a key to be programmed. Alternatively, we could have a system where the user needs to press a key, which would highlight it on the interface and allow the user to set a command.

The spec has not changed in the last week, and no additional costs have been incurred.

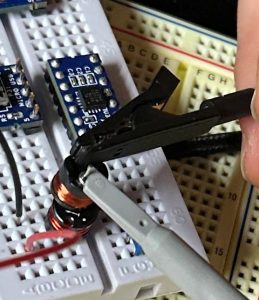

Attached below are photos of the key programming interface prototype and the key housing prototype.