This week Question:

Inductive coil: Issues this week were unfortunately soldering issues to create a good pin output to the breadboard with the inductive coils. A few of the solder pads were ripped off due to uncareful measures, but that is just technical difficulties. That’s caused some slow down with circuit testing

We were able to measure the output of the oscillator chip directly (XKT-412) which we determined is similar to a 555 Timer due to it’s constant output. This denotes that our issues with inductive charging is with the power amplifier. Because of the larger resistance of the smaller coils, it affects how the power is transferred. We are still looking through some literacy to understand what could be helped with this, I’ve been referencing some of my 18-421 notes about common source amplifiers to see what the specific remedy could be and if it is just the common source amplifier or if it could have multiple power amplification stages.

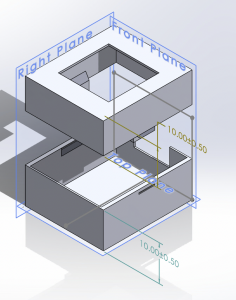

3D Housing: After multiple runs through faulty 3D printing machines and a good print, I’ve determined the walls were made much too thin. I’ve thickened the walls to go from 1mm to 1.25mm and the back wall (which was thinner to account for a longer piece) to be at least 1mm now.

Printing a 1mm wall works fine, but a .6mm wall did not print anything out. Changes shall be printed out on Sunday to see if the results have changed. The picture below is a photo of the schematic of the housing, a hole at the top fit to the key switch to pop out, two sides of locking to fit the top to bottom, and a half hole through the wall for the USB-C port.

I’ve also learned VMware is much more useful than realized so that is a new tool I’ve been using.

Progress has been a bit slow. It’s been a bit frustrating as we thought buying and making changes to a prebuilt board would be easier but I see now that looking at chips like a magic box is not the whole picture. It’s important to know what is necessarily going on in each portion to gain understanding and make changes accordingly. The previous tests have mainly been checking what changes if we change what but that doesn’t necessarily add to understanding as we need to know how each different result is being made.