This week JP and Logan linked up in person to begin the fabrication process. We laser cut our external housing and modeled the internals. The external housing is cut from 1/4″ plywood with 8x8x21 inch dimensions (external length). We decided that it would make fabrication and mounting the camera easier if we constructed the housing as a rectangle and just made the internal parts with an internal circle that can freely rotate. Currently it is clamped and we are giving the glue time to dry properly.

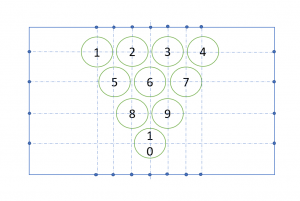

We also discussed an algorithm for displaying cups in the proper place on our UI. We decided we need to make a simple calibration map/image so the camera and place the cups in pre-defined cup locations based on each formation. As seen in the image below, our calibration map will line up cups based for far way a cup ellipse center is relative to the closest intersecting lines.

The codebase is fit to cross compile for windows x64 and linux arm64 so this will make integration and testing easier since we use both personal laptops and the jetson nanos to run our application.