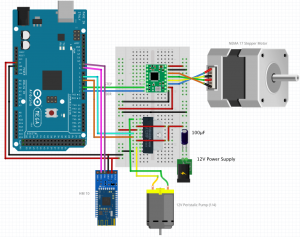

This past week, I made some significant progress on the Arduino program used to control our sliding platform and peristaltic pumps. I was able to successfully select a drink from our phone application, have the pumps dispense the proper amount of each liquid needed to create that drink, and finally move the drink on the platform to our mixing station. I also spent some time with Aryan installing more shelfs in our wooden enclosure to house our breadboard and ELEGOO Mega. Additionally, I prepared and presented for our team during the final project presentations in class this week.

Over the next 2 days, I’m planning on installing our mixing subsystem in our wooden enclosure and making any final touches we may need on the hardware side of things for our video due Monday night. I’ll be further planning and filming our video, polishing up our poster and will be performing some final testing once our subsystems are finally all integrated together.