The portions of the project for which I am responsible remain on track or ahead of schedule. The objectives I focused on this week include:

PROJECT TEST PLAN: I wrote the BARI Test Procedure document, outlining a set of ten quantitative tests that we will perform at various points throughout our project to verify System Requirements. In my section of the proposal slides (metrics and testability), I linked these tests to the System Requirements they verify. Most tests remain as outlines, but several are fully written out with instructions for recording results.

PRE-AMPLIFIER: I have selected an overall topology as well as specific components for the BARI pre-amplifier functional block. Through the use of a switched gain block and attenuator, the pre-amplifier will achieve tunable gain to within +/- 1 dB across a 70 dB range. See Slide 8 of the Proposal Slide s.

s.

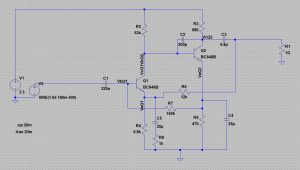

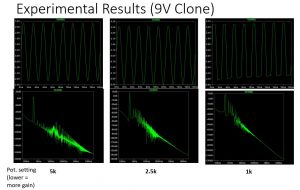

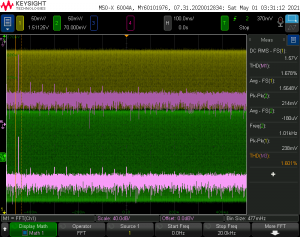

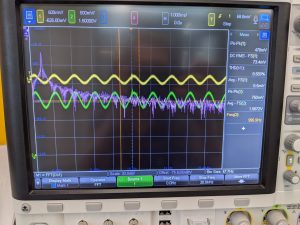

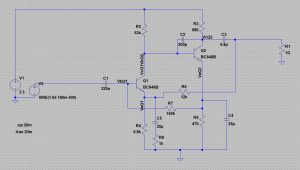

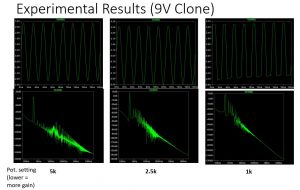

ANALOG EFFECT: Sam helped me downselect to the “Colorsound Overdrive” pedal, an analog effect that is only available in expensive pedals and will be an excellent selling point for our product. We have reference schematics from  several sources for the Colorsound, but it’s my responsibility to (1) Verify the correctness of these schematics and create a Reference Overdrive Pedal model in SPICE, and (2) redesign the circuit to function at 3V3. (The original circuit runs from 9V.) As of right now, I’ve subdivided the Colorsound

several sources for the Colorsound, but it’s my responsibility to (1) Verify the correctness of these schematics and create a Reference Overdrive Pedal model in SPICE, and (2) redesign the circuit to function at 3V3. (The original circuit runs from 9V.) As of right now, I’ve subdivided the Colorsound  Overdrive into three stage (fuzz face, tone stack, and output amplifier), and I’ve created both 9V and 3V3 versions of the fuzz face stage.

Overdrive into three stage (fuzz face, tone stack, and output amplifier), and I’ve created both 9V and 3V3 versions of the fuzz face stage.

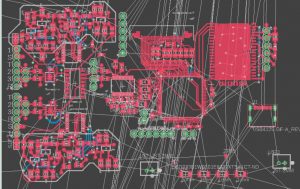

REV 1 SCHEMATICS: This weekend I am beginning to work on schematics for our Rev 1 circuit board, which should be a fully functional prototype of the system. I have an aggressive deadline to complete these schematics in time for a schematic review on 3/1.

In the coming week, I plan to focus entirely on finishing my redesign for the Analog Effect and finishing the Rev 1 Schematics. This will also enable me to help the team create power and fiscal budgets, since the Rev 1 (and Rev 2, if necessary) boards will be a large part of those budgets.

s.

s. several sources for the Colorsound, but it’s my responsibility to (1) Verify the correctness of these schematics and create a Reference Overdrive Pedal model in SPICE, and (2) redesign the circuit to function at 3V3. (The original circuit runs from 9V.) As of right now, I’ve subdivided the Colorsound

several sources for the Colorsound, but it’s my responsibility to (1) Verify the correctness of these schematics and create a Reference Overdrive Pedal model in SPICE, and (2) redesign the circuit to function at 3V3. (The original circuit runs from 9V.) As of right now, I’ve subdivided the Colorsound  Overdrive into three stage (fuzz face, tone stack, and output amplifier), and I’ve created both 9V and 3V3 versions of the fuzz face stage.

Overdrive into three stage (fuzz face, tone stack, and output amplifier), and I’ve created both 9V and 3V3 versions of the fuzz face stage.