Risks:

With regards to the integration of the project components, the principal risk consists of coronavirus-induced shipping delays that could keep us from obtaining missing components on short notice. This is primarily being mitigated by having frequent discussions with one another (and especially Kenny) about parts that are missing or still in-transit.

Last week, we wrote about the increased distance between team members causing significant communication delays. This was addressed by first re-examining our regular meeting schedule, and updating it to reflect our present availabilities. Secondly, we set up a Google Form at https://forms.gle/HW3D9axC5a3YqB7x8 to serve as a rudimentary ticket system for team issues. Tickets are directed to a Google Spreadsheet within our Google Drive directory for later approval.

Changes to system:

This week, Kenny determined that the NEMA-17 400 step motors that we ordered earlier this semester are necessary to implement the panning and tilting functionality of our camera mount. This precludes the possibility of using the smaller 4096-step motors + pcbs that we ordered earlier. Because of the long shipping times associated with the cheaper manufacturers that we’d have to use to spin out the large PCBs that were designed earlier this semester for driving the NEMA-17 motors, we decided to have Kenny implement rudimentary H-bridges on a breadboard using through-hole components. Due to the timing with which orders are placed in this class, this change does not impact our schedule. Indeed, the new through-hole design has already been validated in SPICE simulation, and simply needs to be converted to a Digikey cart for ordering. The risks of implementing H-bridges on breadboard will be mitigated by using separate breadboards for each motor driver to avoid crosstalk, and a relatively large gate resistor was specified for the H-bridge MOSFETs to damp up to 50 nH of parasitic inductance at the FET gates (the circuit node that’s most sensitive to parasitic inductance). Note that this 50 nH corresponds to roughly 5 cm of wire (going by the classic approximation of 1 nH/mm for bond wires).

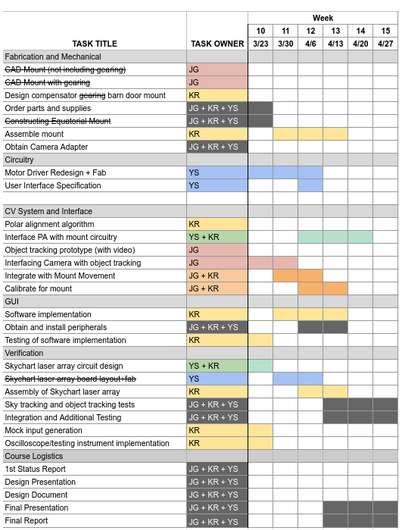

Changes to schedule:

The “assemble mount” task has been extended to Week 13 to allow for the arrival of the final mount components, while the laser array board layout task has been struck through to reflect our decision to have Kenny simply solder together through-hole components to implement the test setup’s laser drivers. Lastly, the User Interface board layout task has been revised to omit mentions of PCB layout, since the rudimentary UI can be implemented with switches on one of Kenny’s breadboards.