My tasks for the week:

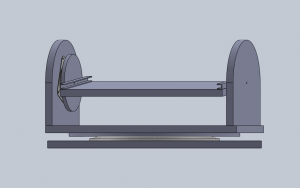

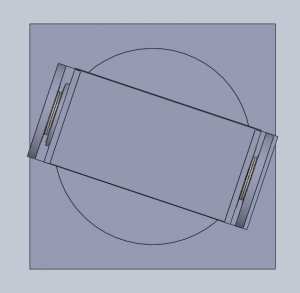

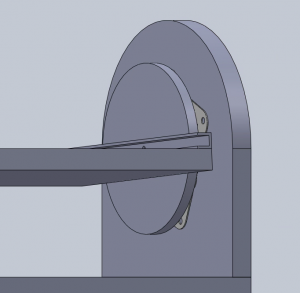

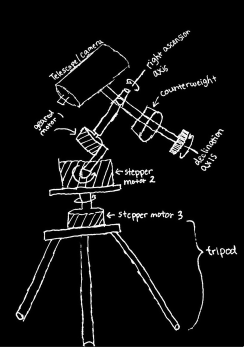

- Design the mount (not including gearing)

- CAD the mount (not including gearing) in SolidWorks

- Figure out which parts must be purchased

- Figure out how to fabricate remaining parts

What I have from this week:

- A very rough SolidWorks assembly of the mount

- Fasteners, some gears, some teeth on gears omitted

- Tentative dimensions

- There is an upper part of the mount that includes Kenny’s compensator gearbox, which is relatively complicated and may take up a bit of space. I have not drawn it because I am not sure how it will fit in.

- A partial list of parts to purchase

- From McMaster-Carr

- 2 square turntables (6031K160)

- 1 round turntables (1544T200)

- 4″ of aluminum U-channel (9001K124)

- Or maybe a different size

- Still need to figure out what screws and other fasteners we need

- From McMaster-Carr

- Ideas for fabrication of other parts

- MDF panels, which can be jigsawed

- Gears lasercut from quarter-inch-thick HDPE

- IDeATe doesn’t allow HDPE in its laser-cutters, but TechSpark does.

- HDPE can be tricky to cut, melting or catching fire on the wrong settings.

My progress:

- I am mostly on schedule. I am not completely satisfied with the design, and there are some uncertainties, but next week is also allocated to improving the CAD and integrating it with Kenny’s gearing designs.

- I am a bit behind. I still need to figure out what size aluminum U-channel, which screws and fasteners, etc. that we require for the mount. I would like to improve the CAD so that it has more detail (e.g., the holes that must be drilled into the MDF panels). I still have not asked my team members for feedback and suggestions.

- How I will catch up: I have Sunday and Monday to figure out parts and improve the CAD.

Challenges/Requirements for the mount:

- Holding up the weight of the photographing equipment as well as the polar aligned compensator.

- Having enough space to accomodate the equipment and the polar aligned compensator.

- Having the 0.5 degree accuracy when positioning.

- Having the torque necessary to lift the equipment and compensator.

Next week:

- Talk to team members about the design.

- Order parts and talk to the right people about fabrication credits for the team.

- Figure out with Kenny how the gearing will integrate with the rest of the mount.

- CAD the mount in more detail.