2 March

Team:

There are a few low risk items currently on the table. Firstly, the latest batch of orders has yet to arrive. We placed them February 20th, and with Amazon Prime shipping we expected all the items in by now. We’ll be following up with staff to ensure we can get these items promptly in order to unblock JT’s and Sam’s portion of the project. Secondly, there were some concerns from the design review that we didn’t have the correct measures to address untuned stepper motors. While this is a possibility, JT has done the necessary research to ensure that each motor turns it’s designated amount. We do not plan on adding a feedback loop just yet.

While waiting on our products to ship has been a deterrent, we still believe we’re on schedule. The core design remains the same. Sam has a few iterations to make to the cube state detection software, but these are mainly quality of life changes. Since we upgraded our power supply for the robot, we do not have any new concrete changes to our system. The power circuit design is to come in the next week. We’ll be sure to address Professor Sullivan’s issues in our design document, but we still believe our current approach is rock solid. Before spring break, we hope to have all the parts and have the basics of each core module completed. Our current estimates believe that we can finish the core robotics and solving algorithms a week or two after break. This leaves plenty of time for construction, assembly, and testing.

JT:

This week was a slower week for my part of the project. I’m still waiting on the orders I place last week, to start getting multiple motors working together. However, in preparation I’ve written a few basic Arduino sketches to turn a single motor arm in the three various ways we need for each face, clockwise 90 degrees, counter clockwise 90 degrees, and clockwise 180 degrees. In preparation for the design review presentation, I put together the majority of the slides in order to keep team and goal consistency with prior presentations. I also refreshed and provided Lily with in depth notes about the overall goals and each core components of the three major modules of the project.

During the design presentation, Professor Sullivan did raise a few questions concerning how we’d ensure proper stepper motor movement. While we don’t plan to implement some sort of feedback loop, we do plan on rigorously testing each individual motor separately to ensure precision. Because we went with fairly straight forward motors, this process should be straight forward. The NEMA-17 stepper motors are only capable of 200 steps in a single revolution, where each step is 1.8 degrees. Unless the motor is fundamentally flawed, we should have no problem ensuring that the motors turn the exact amount we need. Even so, to combat this we made sure to order multiple motors in advance.

Lastly, I started documenting all the necessary steps for the robot construction into our Design Document. I also updated the current block diagrams and graphics we used for the design review presentation to be more current and in depth for the paper. After writing multiple pages, I’m waiting on my groupmates to add to their sections so I can ensure the paper is cohesive and complete with what we’ve gathered so far.

I do believe my progress is a little behind as of this week solely because I’m still waiting on the new power supply for all the motors. I hope to get in touch with Evan or Quinn soon to make sure that nothing was misplaced. Next week is spring break, I absolutely believe that I’ll have motors working and an even stronger understanding of what needs to be done to get all 6 running smoothly after spring break.

Lily:

The following is a brief review of the solver’s function: The cube state string configuration will be fed into the solving program, which will instantiate a Cube object and identify the individual cubie pieces and locations. From there, the Beginner’s method solver will proceed to solve the cube state by layer, based on pre-existing algorithms for each layer and sublayer, all while concatenating a string of moves. Once the cube object reaches its fully solved state, the resulting string of moves will be used for physically solving the cube by the motors.

This week, I fleshed out the class definitions and changed the mapping order for the cube configuration string. I resolved my cubie implementation issues from last week and was able to write the start for the rotation moves and the actual Beginner’s method solving algorithm. After consulting with my group, we’ve come to the conclusion that my feelings of being behind in my implementation is a bit premature: since it will take us a while to get the driver-motor setups working, in addition to Sam’s recent changes to his cube state detection subproject, my solver subproject is going swimmingly.

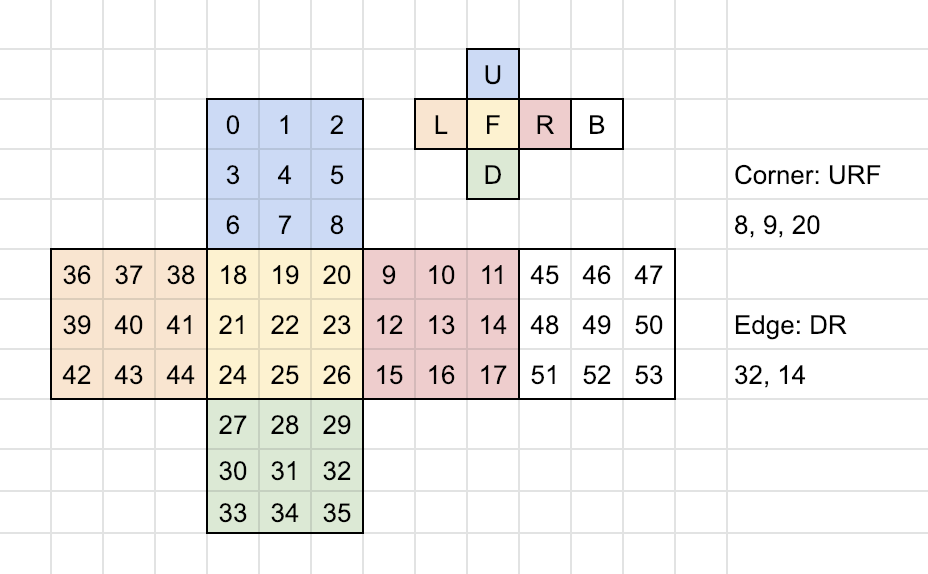

Figure 1: New cube mapping order for the right face [R]

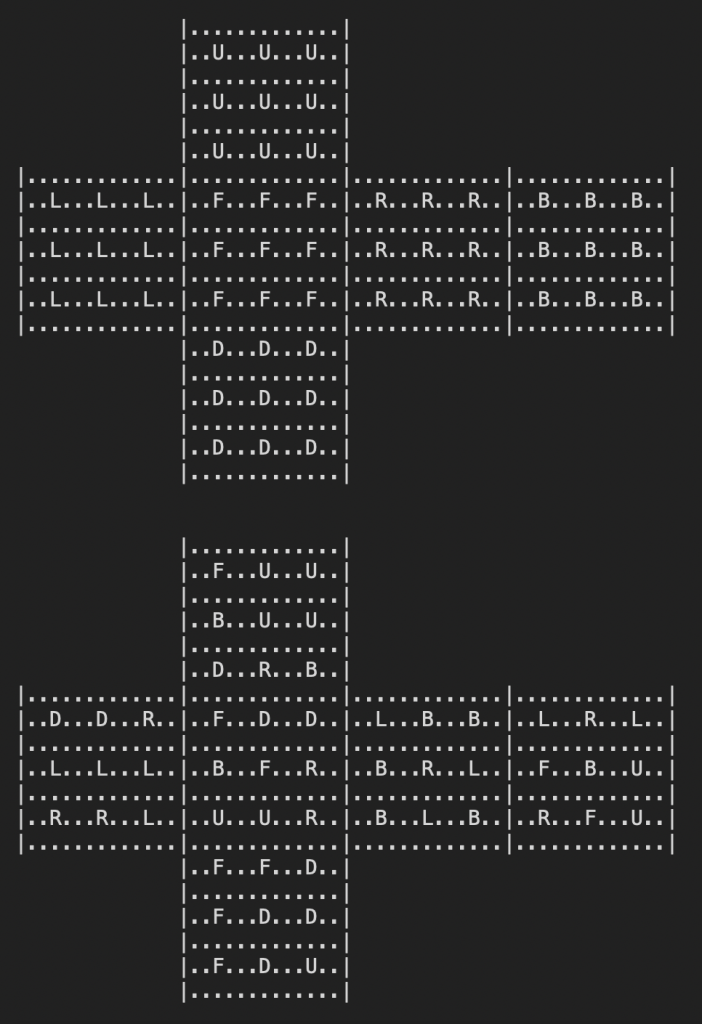

I added several functions that allow us to print out an ASCII unfolded cube representation of the given cube configuration based on the order of characters in the configuration list. Doing so will allow us to verify and ensure that the “before” and “after” cube states for each rotation move execute as planned and also increase the readability of the software for testing purposes. Figure 2 gives the ASCII displays of the cube state given the following configuration strings:

UUUUUUUUURRRRRRRRRFFFFFFFFFDDDDDDDDDLLLLLLLLLBBBBBBBBB (fully solved cube)

FUUBUUDRBLBBBRLBLBFDDBFRUURFFDFDDFDUDDRLLLRRLLRLFBURFU (a scrambled cube)

Figure 2: ASCII displays of cube configuration

In preparation for the design review presentation, I was brought up to speed on the workings of the cube state detection subproject and what’s to come for the hardware portion. Two points of interest from our design review presentation feedback brought the issue of stepper variance and a CAD model for our motor housing. This coming week, I’m slated with designing the power circuit such that we can provide enough current and power to each of the six driver-motor setups. For the circuit design and the design review presentation feedback, I will be working closely and consulting with JT.

With all of this in mind, I believe that we’re on schedule to finish as planned. I am nervous about the hardware and CAD portion but I think we have adequate resources to complete our project and create a decent demo as planned. This upcoming week, I anticipate starting and perhaps completing the following: the design and prototyping of the power circuit; taking measurements of the motors, motor drivers, and the cubes for the housing CAD model; and completing more of the Beginner’s method algorithm.

Sam:

This week, we had our design review so I spent time detailing the cube state detection part of the project and created slides for the design review. I also informed the Cubr team of all the cube state detection details and brought them to speed on all the implementation details. I also started research on the communication from the Mac to the Arduino when we want to pass the solution string from our software to the robot that will solve the cube. I am confident that by the end of next week, this will be fully fleshed out and implemented.

Lily detailed JT and I with her solving algorithm and I learned about how the Object Oriented Programming in our solver software is working. This overview gave me a very clear picture of how our project is going to work and what else needs to be done so that we ensure we finish on time. Our progress is on schedule and we do not have any part of the project that we haven’t thought about. In other words, there are no unknown unknowns.

In the upcoming week, I will completely flesh out and implement the communication between the Mac and Arduino. I will also help JT with the hardware component of the project this week as this will be the part of the project we are the least comfortable with as we are all software oriented. I am anticipating for the soft lighting box to get in this week and will finalize the HSV values needed for the cube state detection for the two main color schemes of stickers we have. I also plan on spending time to design a solution for the physical infrastructure of our project. This includes the housing for the cube and motors and can be designed using CAD or 3D printing.

I have also added to the design document alongside JT and Lily. We have been working on this document extensively and have all been discussing our respective parts of our project so that we are all on the same page. Collectively, we are on schedule and are hoping to have another productive week.

0 Comments