This past week, I worked alongside Marco and Angela to clearly scope out our entire project design, identify trade-offs in our choices, and redefine our priorities to finish the design doc, begin our audio processing, and ultimately finish our project on time. In the week before fall break, we set a team deadline to finish and test our proof of concept design before our design doc was due and start on the audio processing component of our project. I was tasked with writing various sections of our design doc as well as those pertaining to my specialized areas (web-app and physical system).

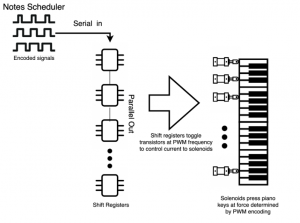

Along-side writing our design doc, I put my time into defining what a successful proof-of-concept design looked like for our physical system and how we could go about designing it. To recall, our physical system will consist of 69 cylindrical solenoids fixed to a solid chassis that will be placed on top of the keys of a piano and activated electronically to press the keys. The solenoids will be controlled from a Raspberry Pi and several shift registers connected to MOSFETs that allow or block current flow into each solenoid. For our proof-of-concept, we ordered 5 smaller solenoids of similar type as our final product, MOSFETs, and Shift registers. Our plan was to use an Arduino and simple programs to drive the shift registers connected to each solenoid to prove that we could not only drive multiple solenoids at once and correctly calculate power-needs, but also to input patterns for solenoid activation that closely simulates the note scheduling we would be doing for the final physical system. After deep diving into spec sheets for our solenoids and shift registers, we were able to successfully program several patterns of activation for our solenoids and time them appropriately. (A video is linked showing the activation of 3 solenoids each second in a simple pattern).

Link to my drive for video showing 3 solenoids activating in pattern.

On top of the proof-of-concept tests with activating solenoids in a pattern, I also implemented a test for seeing how fast the play-rate is for 1 solenoid. This would affect how many sounds we could produce per second. As Angela found out, the English language can speak up to 15 phoneme (a phoneme is the smallest unit of speech distinguishing one word / word element from another) per second, which may require us to produce up to 15 sounds per second. This test confirmed that we are able to reproduce this upper bound if necessary. (A video is linked below showing the solenoid play rate at 16 times per second).

Link to my drive for video showing play rate at 16Hz.

Overall, these experiments have given us confidence in our ability to design and create the overall physical system reliably. We have also discovered some helpful resources along the way (thanks to an online forum of self playing piano makers that Marco found) that have allowed us to focus less on the physical design of the chassis and more on our unique circuity idea, audio processing, note scheduling, and web app.

For the remainder of the Fall break and the following week, I will be helping to plan out the audio processing and note scheduling as well as setting up the web app for hosting the above mentioned systems.