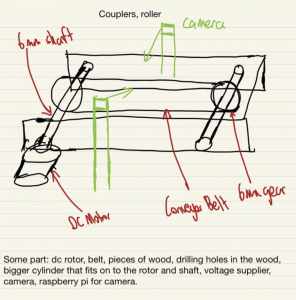

The most significant risks that could jeopardize the success of the project at the moment is we are falling behind on our initial schedule. We are a bit indecisive and because both Jiyeon and Rachana don’t have a solid background in image recognition, we could not come up with a solid design plan, and every time when we talked to the professor and the TA in the status meeting, we were not sure what would be the best solution and how to tackle the obstacles. However, we are confident that we can make much more progress as we have a solid design plan set up. One of the concerns was a hardware design. Last week after the proposal presentation and meeting, we realized that we need a conveyor belt to scan the product one by one. Raymond looked for a conveyor belt that we can use, but he couldn’t find one with a reasonable price. Professor Mukherjee showed us last year’s capstone project that built their own conveyor belt and suggested us to build one. Thus, we will be building our own conveyor belt for our project and we decided to get rid of using a weigh sensor.

This is a brief sketch of our design with a conveyor belt:

Now we have decided that we are going with a conveyor belt and no weigh sensors and we have a dataset for retail product, we are feel confident to get back on schedule– especially because we initially planned our schedule conservatively with more extra time.

Here’s our updated schedule until the design presentation. We did not need much change as we initially planned our schedule with lots of flexibility.