This week, I helped the team prepare for and present our demo to the two groups on Monday and Wednesday, as well as work on modifications to the device to solve swinging problems in the air.

On Sunday before the demo, we worked together to fine tune the demo setup by testing what thrust to use, and how high up to tie the device to appropriately show off our system. Additionally, we ran various tests to see if the system performed as expected, as Vikram and I moved the circle under the device, and Lahari modified the detection code accordingly to improve detection. For the demo itself , I gave a brief overview of the main components of our project, then explained specifically my part (the vectorization algorithm), and how it fits into the overall data pipeline (my algorithm receives data from the CV subsystem, and passes it onto the arduino via UART).

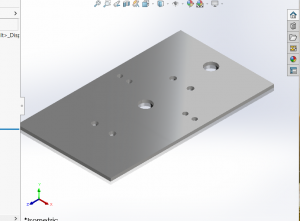

After the demos, due to the low thrust we measured for each of our motors using the smaller props (~220g), I researched various thrust tests to see what other people were getting. I noticed people were getting easily over 800g using our motor with a 4S LiPo and 5 inch props (like us), so I suggested to the team that we should construct a proper motor thrust setup (motor attached to a raised platform, with a flipped propeller to generate thrust downwards onto a scale. Lahari and I found a wooden rod, and with the help of a friend, cut it to an appropriate size. I then measured the middle of a rectangular platform and glued the rod to it to give it a solid base. We then attached the motor to the top, and ran several tests. We found 330g of thrust with the 3S LiPo (the 4S was low battery), and 400g using thicker wires for the ESCs.

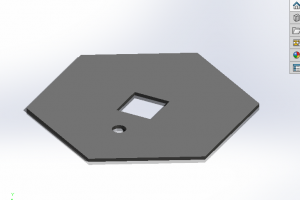

In order to solve the swinging problem we noticed in the air (which we attributed to lightness), we thought it would be beneficial to add weight to the device. I suggested we could use fish aquarium rocks (which I knew Lahari may have) as a stand in for the payload. We measured three 200g bags of rocks, and Lahari and I cut a hexagonal insert such that we could put the bags at the bottom of the device, and cover them with this platform. After this, we tested the device off the bridge (I dropped it, Lahari initiated it and Vikram caught it) and noticed the swinging no longer occurred, but minimal to no movement was observed. We then found that the 4S LiPo was low battery, causing the motors to slow down mid flight, so we charged it. Our next tests will have a fully charged battery, and 2 instead of 3 rock bags; we will then change thrust and weight accordingly to what we observed.

I also helped the team run detection tests for the circle off the Pausch bridge. I held the device off the side as Lahari viewed the camera feed on the laptop and made on the fly edits to the detection code. We found that the circle was too small to be detected in the thresh-holded image, so we printed a circle two times the size (2 meter diameter), and will be testing with that as soon as we construct it.

Lastly, I researched and ordered larger propellers (7 inches) in order to increase thrust further, incase we still cannot move after lowering the weight and using a fully charged battery.