Team

No change has been made since last week.

We are on the Schedule.

- Fine-tuning the vision pipeline

- Currently, the trajectory estimation still has a 15cm error and a 20% false-negative rate.

- Sometimes due to the different initial throwing points and throwing patterns, the vision pipeline cannot detect the landing points of the ball.

- We suspect that before throwing a ball, most people may have a pre-motion which is a downward movement. This downward movement sets the Kalman Filter with an unexpected covariance and a large downward speed.

- So, it makes the later parabolic trajectory generation and estimation harder due to this pre-motion.

- Our current idea is that we should use some way to let the Kalman Filter self-correct this pre-motion or filter out this pre-motion for the Kalman Filter.

- Another problem is that the current Kalman Filter only recursively predicts the state based on only one previous tracked point.

- We designed it in this way for the purpose of time-saving.

- However, by estimating the trajectory based on all previous tracked points can make a better landing point prediction and does not spend more time than the previous method.

- So, we decided to change the trajectory estimation to use all previous tracked points.

- Fine-tuning the drift of the car

- As we said in the last status report, our car has some large drift that cannot be controlled during side movement.

- We found out the following three reasons and had corresponding solutions.

- The first reason is that the center of the mass of the mobile platform changes dramatically. The problem with the shift of the center of the mass is that not all wheels contact the ground with the same surface. So that they can not provide the same force during side movement.

- We now recalibrated the center of the mass of the mobile platform once in a while using four weight scales.

- The second reason is that the floor is not even, does not provide enough friction and should not be too hard.

- We tested many different floor type

- Acrylic

- Acrylic with Tape 1

- Acrylic with Tape 2

- Cardboard (This is the best floor)

- The last reason is the suboptimal PID value.

- We decrease the value of D and add 0.01 to the I

- The car’s movement becomes much better.

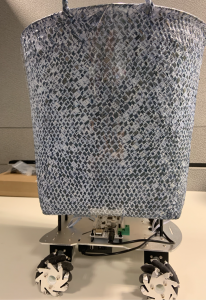

- Finding a better-sized trash can

- The requirement for the trash can outer diameter’s size is around 30 cm.

- For convenience reasons, we decided to use the IKEA standard trash can for testing.

- However, the current IKEA standard trash can’s outer diameter is only 27cm.

- A lot of the trashes hit the outer rim of the trash can during the test and in-lab demo. So we decide to increase the trash can’s outer diameter to around 30cm to 35cm in order to increase the accuracy.

- Integration Test

- Tested the latency of the entire system. The platform starts moving approximately when the ball reaches the top of the parabola, which is fast enough for the platform to catch the ball.

- Tested the success rate of catching the ball. The success rate is around 50%. The reason why it has not reached 80% yet is due to trash can size issues and false negative in trajectory estimation.

- Tested behavior of trash can movement. Trash can return to the designated position and does not move outside of the designated area.

- Finish the final report

- Finish the final presentation

- Finish making and printing the brochure

- Deliverable for next week

- Public demo