What did you personally accomplish this week? Give files or photos that demonstrate your progress. Prove to the reader that you put sufficient effort into the project over the course of the week (12+ hours).

- This week I worked on validating the sensor array setup. I built a small mockup in the lab as proof of concept. Here is the link to some pictures:

- https://drive.google.com/drive/folders/14LiZyGlgnzooL9NhAiBFkcnJIqBjcocY?usp=sharing

- I created a 4×3 sensor setup. Our initial idea was to have the sensors space ~4 cm apart. However, after this analysis, I realized that we could easily get a few more centimeters to reduce the total number of sensors in the setup. Instead of using a decoder to sweep through different sensors, I just brute force connected the sensors to the analog pins on the Arduino and viewed how they changed as I moved a test device across the setup. Here is the code I wrote:

- https://drive.google.com/file/d/1c4kG5jKd9p7qzwbsMP-pJRLiSsfu-SFV/view?usp=drive_link

- I experimented with different sensor distances, and for now have concluded that 5-6 cm between the sensors is good enough. This significantly reduces the number of sensors we will need to use.

- I also validated that we would be able to use at least a primitive way of triangulation for device location based on the relative signal values of hall sensors nearest to the device.

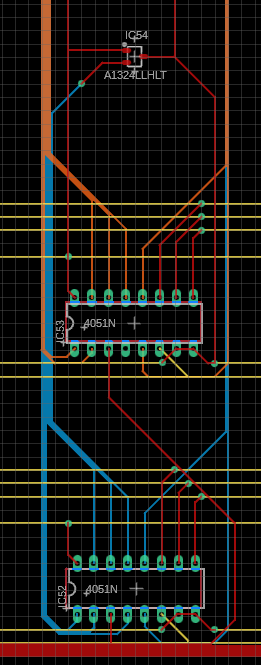

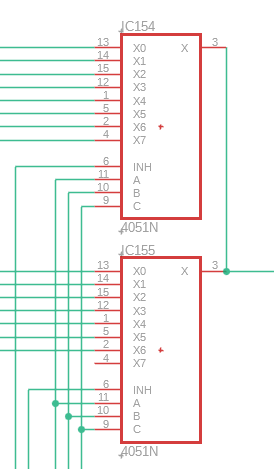

- Me and Callum also deliberated the decoder setup further and have a much more concrete idea of what it is finally going to look like. Callum has also created a schematic of how everything is supposed to connect.

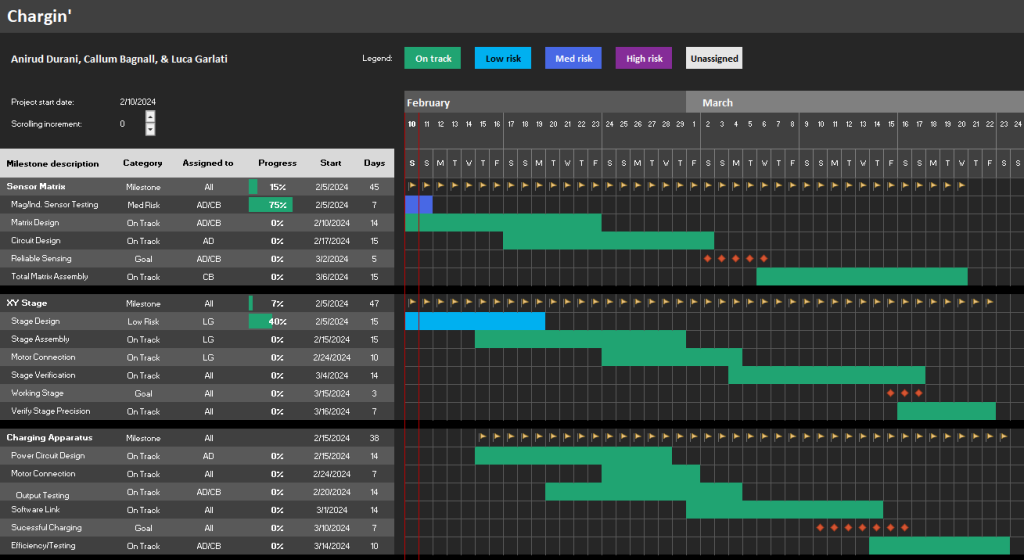

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

- I think my progress as well as that of our team is on schedule!

What deliverables do you hope to complete in the next week?

- Next week, if the charging coils come in, I want to finish testing and characterization. I want to see the actual effective range of different power values. I also want to see which layers and how many of them we can put in between the device and the coil before it stops charging at a fast enough rate. I also want to figure out a way to tap into the coil breakout PCB to utilize the charging current as a parameter for validation.

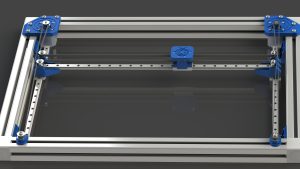

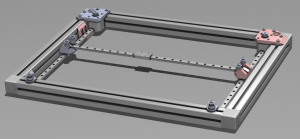

- I also want to start assembly of the sensor array setup.

- I also want to start working on the sensing code with Callum. We need to create a good interface between the decoders and the Arduino that will allow us to reliably sweep through different locations and make a location estimate based on signal values.