- What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

- We are spending a lot of time designing, which is not necessarily a bad thing, but we might be underestimating the amount of time needed to do the assembly. We have slack time built into our schedule, but we don’t want to be in a situation where we get held up to for a large period of time. We are trying to expedite our design process without compromising on details and trying to get the parts ordered ASAP.

- Another concern is that the 3D printed parts might not be strong enough to hold everything up. We are ordering enough filament so that we can re print parts if needed. We have also found metal replacements in case we need to order those (in the situation that plastic is not strong enough altogether)

- We are working on the CAD models as much as possible with the listed dimensions for the parts. However, there may be errors in manufacturing that might prevent the components from integrating together properly. We are trying to account for this as much as possible by making parts that might be able to work even with minor errors in manufacturing. We are also trying to order parts that are as precise as possible. The extra filament also helps it we need to redesign and reprint parts.

2. Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc.)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

- Initially, we had envisioned a PCB that would house the sensing array and be placed under the surface of our table. We were thinking of bolting it to the underside of the surface using some type of adhesive. This, however, would introduce two problems: 1. The hall sensors wouldn’t be as close as possible to the device 2. We would be introducing yet another relatively thick layer between the charging coil and the device, thereby reducing efficiency.

- To mitigate some of these issues, I was looking into Ultra-thin flexible PCB’s and Copper Core PCB’s. The idea was to reduce thickness and possibly improve coil coupling by introducing a metal layer. These, however, were proving to be too expensive, especially with parts assembly. I took quotes from different websites and realized that the cost was too much for the benefit it could possibly provide.

- So, we reevaluated our design and have come up with two possible alternatives:

- Flexible plastic sheet to stick the through-hole components onto. We can then use flat wiring to connect these to the decoders and peripherals.

- Laser etching indents into the underside of the tabletop surface to house the components and wiring. This second option is a little more tedious mechanically but could possibly improve the sensing efficiency due to more proximity between the sensors and devices and improve the elegance of the project.

3. Provide an updated schedule if changes have occurred.

- No changes so far! Yay!

4. This is also the place to put some photos of your progress or to brag about a component you got working.

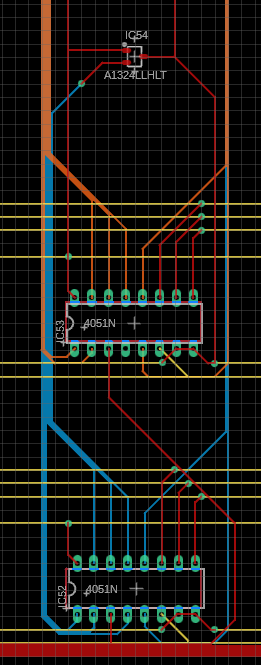

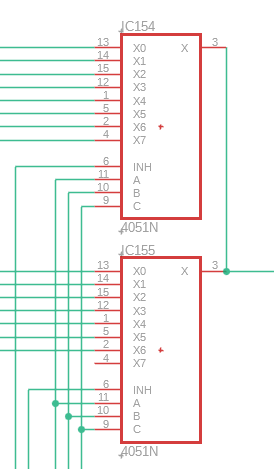

Snippets of sensor matrix diagram

A was written by Callum, B was written by Luca and C was written by Anirud.

Part A: CALLUM … with respect to considerations of public health, safety or welfare. Note: The term ‘health’ refers to a state of well-being of people in both a physiological and psychological sense. ‘Safety’ is the absence of hazards and/or physical harm to persons. The term ‘welfare’ relates to the provision of the basic needs of people.

By using the Qi protocol to identify compatible Qi chargers above our charging coil, we will avoid inductively heating any metallic object that is placed on the table. This will reduce the likelihood of temperature hazards, whether they are burns or fire. We are currently discussing the use of a heat sink on our wireless charging module to further reduce heat hazards, but we need to test our charger to see if such a system is necessary.

Part B: LUCA … with consideration of social factors. Social factors relate to extended social groups having distinctive cultural, social, political, and/or economic organizations. They have importance to how people relate to each other and organize around social interests.

I’m not sure if this entirely applies to our project. It’s not something brought out into public, it’s not a necessity, and would not be impactful on how people would interact with others. It’s a pure convenience device, and would likely be priced as such if it were a real product. The only interaction others would have with this device would be in someone else’s residence. Even then, unless explicitly pointed out, guests would simply think it’s a normal table. Ideally, they wouldn’t even notice their phone was charged once they pick it up.

Part C: ANIRUD … with consideration of economic factors. Economic factors are those relating to the system of production, distribution, and consumption of goods and services.

When considering the economic factors of our wireless charging tabletop, several key aspects come into play:

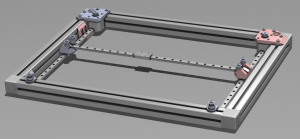

- Production Efficiency: By integrating advanced technologies like hall sensors and an XY stage, our tabletop can potentially optimize production processes, leading to cost savings through increased efficiency and reduced waste. Additionally, leveraging modular design elements could facilitate easier assembly and scalability, further enhancing production efficiency.

- Cost-effectiveness: The implementation of wireless charging technology may initially incur higher manufacturing costs compared to traditional charging solutions. However, by optimizing production processes and leveraging economies of scale, we can work towards reducing the overall cost per unit, making the product more accessible to consumers while maintaining profitability.

- Distribution Channels: Partnering with established tech retailers, furniture manufacturers, or even hospitality businesses can provide access to diverse distribution channels, enabling us to reach a wider audience and increase market penetration. Additionally, exploring direct-to-consumer models through online platforms can offer greater flexibility in reaching target demographics.

- Consumer Adoption: Understanding consumer behavior and preferences is crucial for driving adoption of our wireless charging tabletop. Conducting market research to identify key consumer pain points, such as the need for convenient charging solutions in various environments, can inform product positioning and marketing strategies to effectively communicate the value proposition to potential buyers.

- Long-term Sustainability: Considering the environmental impact of our product throughout its lifecycle is essential for sustainable growth. Implementing eco-friendly materials, designing for recyclability, and minimizing energy consumption during use are all factors that can enhance the product’s appeal to environmentally conscious consumers and contribute to long-term economic sustainability.