This week went very well as well. For our demo we wanted to have was a full demonstration of the putter setting up their ball, taking their putts, and tracking the distance with the webapp. We then wanted to demonstrate the sensor system to tell when a putt is made. Finally, we wanted to have a demo of tracking spin rate and putter speed with the IMU.

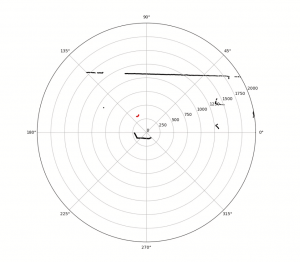

After a laborious Sunday, we were able to achieve most of these goals. It started out for me by walking the entire course down Forbes with a few of my friends after realizing the 10 foot by 5 foot course wasn’t going to fit in the back of my car. Going to call that walk my workout for the week, grabbed some food and it was off to the lab. We set up the course and configured the LiDAR. Leveling the course was harder than expected as the LiDAR needed the entire course to be very level in order to properly find the outline. Once that was done, I finished implementing an algorithm to calibrate based on the course outline and search for “ball-sized outliers”.

Now that we had this performing, we set up a small LED system to represent the RFID and the pressure sensor being triggered before trying to configure them with the webapp. Seaver spent some serious hours getting the webapp to work and deployed.

Finally, we threw some post requests into our codebase for the LiDAR and Arduino based sensors to communicate with the webapp. Our downfall pre-demo was the operating the IMU. Unfortunately, we did not receive our batteries in time so that made it impossible to communicate with the IMU while it was in the ball. We were pretty burnt out by this point anyway, so we set up a small sub-demo of the IMU where it was still wired up.

Overall, we are set for the coming month and have some work ahead of us. Next big tasks are working with the IMU once we receive the batteries and putting the felt on the green to slow the roll of the balls. Regardless our schedule is on track, but we will need to make a push this week with testing.

The next tests for me to perform are verifying the distance measurement of the LiDAR and the accuracy of the IMU.

Our LiDAR test is quite straight forward, we plan to place the ball in 25 different spots that vary both distance and angle to the hole, measure the distance with a tape measure, then measure the distance with the LiDAR. From there we can continue to calibrate or verify that it is within our specification of 3 centimeters from the true distance.

The IMU test is a bit trickier, for this we will roll the ball along a path of length 3 feet and time it. This will give us the average speed over that distance. We can then extrapolate the spin rate as this will be based on the speed and circumference of the ball. Comparing this to the measurement of the IMU will tell us if we are within 5 revolutions per minute as per our specification.