This week I worked on getting more than 7 devices to connect to one central BLE receiver. However, I was ultimately unsuccessful. The first thing I tried was to modify the values in the MbedOS configuration for the Arduino Nano33 BLE boards that I received this week. However, the issue was that to recompile the MbedOS required installing a certain set of depenedencies that were no longer possible. After failing to modify the MbedOS configuration, I instead looked towards trying to modify the ArduinoBLE library to allow multiple connections. I tried changing the ATT_MAX_CONN value first to 8, but that ultimately ended up not doing anything. Then, I dug deeper and looked into what exactly the library was calling, and where connect was failing. I found that the problematic function was in the HCI class’s leCreateConn function, which had would return the value of a call to sendCommand. sendCommand would return the value of _cmdCompleteOpcode, and after some digging, I found that this value was set by the handleEventPkt function, specifically in the EVT_CMD_COMPLETE case. However, I was unable to locate where exactly the value was being written, since the value is assigned to a value passed in through an array that was read into from HCITransport.read. However, I was unable to determine where this value was being read from and how I could ensure that it would not return a result that would lead to the connection failing to be established.

I am still on schedule as it is not essential to have one device connect to more than 7 keys, as multiple receivers can be used. However, I would like to get the number up to at least 8 since that would mean that only 2 receivers would be needed.

Personally, I will be running the tests involving latency and battery life. I will measure latency by recording the process of pressing a key with my phone slow-motion mode, and then counting the frames until it shows up on the screen. Each frame would be 1/120th of a second, so multiplying the frames by 833uS would give me the latency. Next, for battery life, I will be testing the overall battery drain over a period of 1 hour. By measuring the analogue input from the battery pin, and comparing it with the max and min values of the LIPO battery, I will be able to measure the battery level. Then, simply by using the keys for 1 hour I will be able to tell how much battery has drained, and thus how much battery life the device has.

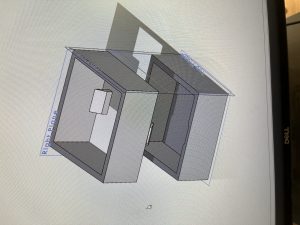

Next week I plan on acquiring more Nano33 IOT boards and developing the connections further. This way, I will be able to test the receiving of more than 7 keys. Additionally, I will also be helping with the housing design and fabrication, and I will be making a few more keys. I can also begin preliminary testing of the latency through frame counting.